How to Implement Extreme Programming in Automotive

Extreme Programming (XP) is an Agile methodology that emphasizes flexibility, rapid feedback, and continuous improvement. Traditionally used in software development, XP's core principles and practices are now being applied in industries like automotive, where adaptability and collaboration are key to staying competitive. In the fast-paced automotive sector, XP’s focus on high-quality outputs and customer-centric development can help manufacturers and suppliers streamline operations, improve product quality, and adapt quickly to changing consumer demands.

In this article, we’ll explore how XP can be implemented in the automotive industry, the key benefits it brings, and how Meegle’s tools can support the adoption of XP in automotive companies.

What is Extreme Programming (XP)?

Extreme Programming (XP) is a software development methodology that aims to improve software quality and responsiveness to changing requirements by using Agile principles. XP encourages teams to work in short, iterative cycles and continuously integrate customer feedback.

By prioritizing collaboration, simplicity, and rapid iteration, XP allows teams to deliver high-quality products faster and more efficiently. Although it originated in the tech sector, XP's emphasis on flexibility and quality makes it an excellent fit for industries like automotive, where design changes and customer expectations evolve rapidly.

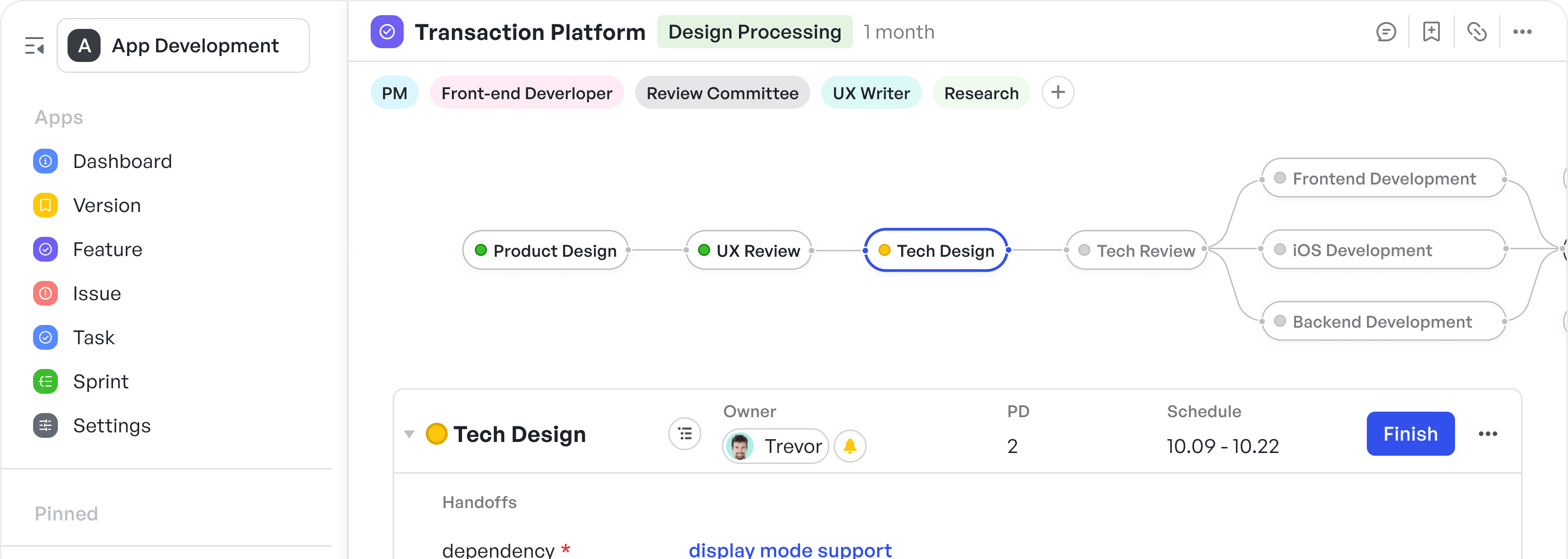

Use Meegle's Automotive Agile Project Management Template for free

Core Values of XP

XP is built on five core values that drive its approach to development and collaboration. These values, when applied to automotive manufacturing and product development, can lead to better results and a more agile workflow.

- Simplicity: XP advocates for the simplest solution that satisfies the current requirement. In automotive, this translates to focusing on designs that meet customer needs without unnecessary complexity, reducing waste and improving efficiency.

- Communication: Continuous communication among team members, customers, and stakeholders is crucial. For automotive teams, this value encourages real-time feedback, collaboration, and quick problem-solving, ensuring that teams stay aligned throughout the development process.

- Feedback: Rapid feedback is key to XP. In automotive, this means consistently gathering customer input and using it to refine product designs, manufacturing processes, and feature sets.

- Courage: Teams are encouraged to make bold decisions, throw away non-working ideas, and try new approaches. This can drive innovation and help automotive manufacturers stay ahead of trends.

- Respect: Respect for all team members and their contributions ensures that everyone is motivated and empowered to deliver their best work. This fosters a collaborative and positive working environment in automotive development teams.

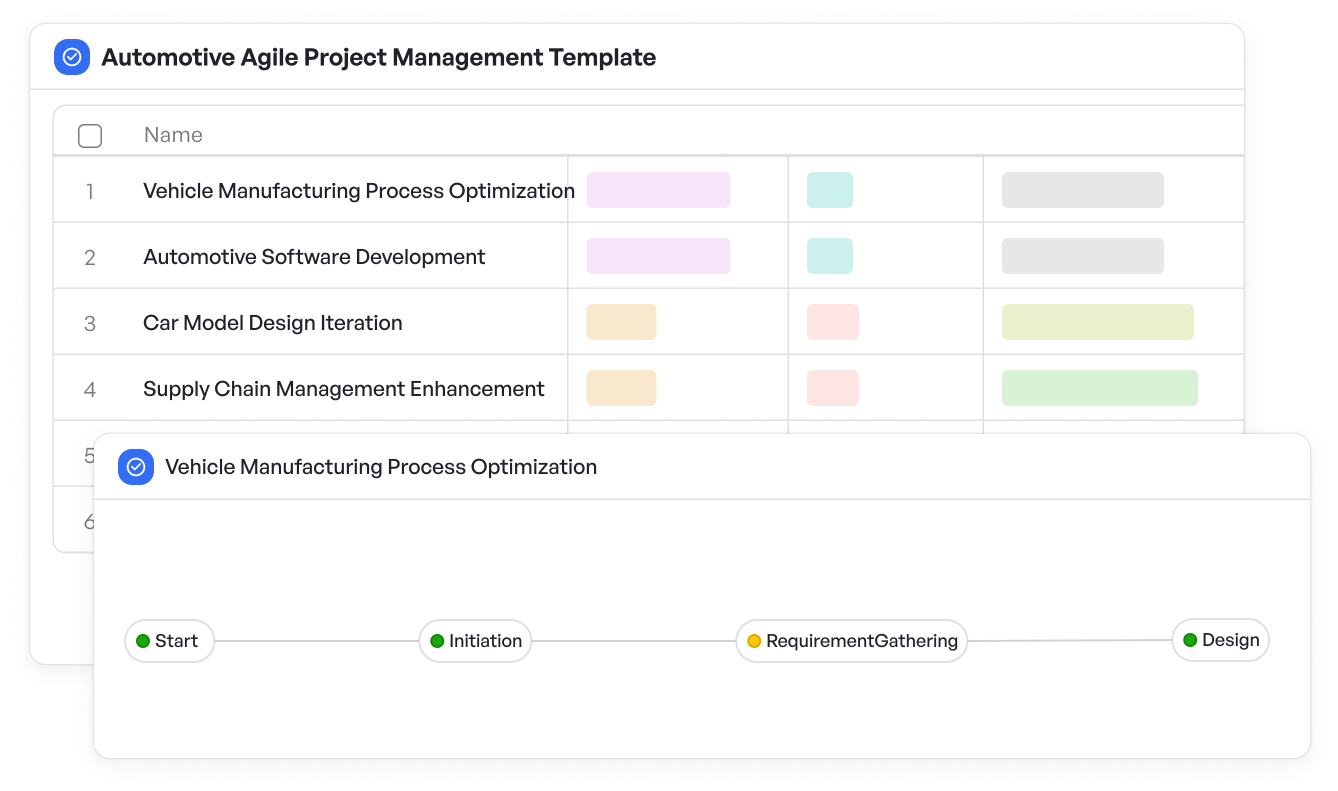

Download Meegle's Automotive Continuous Improvement Template for free

Fundamental Practices of XP

XP is guided by several key practices that drive the principles mentioned above. In the automotive industry, these practices can help optimize both product development and manufacturing processes.

1. Test-Driven Development (TDD)

TDD involves writing tests before writing the actual code. In the automotive industry, TDD can be adapted to ensure that each component of a vehicle or system is rigorously tested before it is implemented. This practice helps catch issues early in the development process, ensuring high-quality outputs.

2. Pair Programming

In pair programming, two developers work together on the same task. This practice promotes collaboration and ensures that work is double-checked for errors, increasing the overall quality of the product. In automotive design, cross-functional teams—such as designers, engineers, and product managers—can work together on tasks to ensure all perspectives are considered and the final design meets all requirements.

3. Continuous Integration

Continuous integration (CI) is a practice where code changes are frequently merged into a shared repository and tested automatically. In automotive development, CI can be applied to integrate new features, design updates, and testing components quickly, allowing for faster development and less risk of defects.

Benefits of XP in the Automotive Sector

XP’s core practices and values offer significant benefits to automotive manufacturers and developers, particularly in today’s rapidly changing market.

1. Enhanced Flexibility and Responsiveness

XP’s iterative approach and continuous feedback loops allow automotive companies to adapt quickly to changes in consumer demands or technology. Whether it’s adjusting to regulatory requirements or integrating new tech features into vehicles, XP enables teams to stay flexible and responsive.

2. Rapid Deployment and Continuous Improvement

With XP, automotive teams can release small, incremental updates to products or features. This means that new car models, infotainment systems, or safety features can be rolled out more quickly, while continuous improvement ensures that future releases are even better.

3. Improved Code Quality through TDD

By writing tests before code, automotive companies can ensure higher quality in their product designs, whether it's software for infotainment systems or vehicle control modules. This reduces defects and the time spent fixing bugs, allowing manufacturers to deliver more reliable products to customers.

Read more: Automotive Total Quality Management Template

4. Streamlined Collaboration with Pair Programming

Pair programming fosters collaboration and knowledge sharing, which is crucial in the automotive sector, where multi-disciplinary teams are involved in the development of complex systems. By working together, automotive engineers and software developers can resolve issues faster and create more robust solutions.

Implementing XP in Automotive Companies

To integrate XP into an automotive company’s existing processes, several key steps must be followed:

1. Integration with Existing Processes

XP can be integrated with traditional automotive processes by focusing on continuous improvement, iterative development, and involving customers early and often. This approach complements existing workflows, such as product design cycles and production planning, allowing for greater flexibility and responsiveness to changes.

2. Importance of Customer Involvement

XP emphasizes the importance of customer feedback throughout the development process. In the automotive sector, this means engaging with customers early in the design phase, testing prototypes, and refining features based on real-world input. By continuously integrating customer feedback, automotive companies can ensure that their products meet market demands.

3. Simplicity in Design

In automotive, complexity can lead to delays and errors. XP’s focus on simplicity in design ensures that every feature, whether it's a car's engine system or its infotainment interface, is built with the user in mind. Simpler designs are easier to maintain, update, and scale.

Challenges of Adopting XP in Automotive

While XP offers many benefits, there are also challenges in implementing it within the automotive industry.

1. Balancing Traditional and Agile Practices

Automotive companies often have long-established processes, and introducing Agile practices like XP can disrupt existing workflows. It’s crucial to balance Agile and traditional approaches, gradually implementing XP in ways that complement existing systems without overwhelming teams.

2. Managing Cultural Shifts

XP requires a cultural shift towards collaboration, openness to feedback, and continuous improvement. This can be difficult for automotive companies that are used to hierarchical decision-making and siloed teams. Successful implementation of XP requires buy-in from leadership and a commitment to fostering a collaborative, cross-functional environment.

3. Ensuring Consistency in Productivity

XP emphasizes collaboration, which can sometimes lead to disruptions in productivity if not managed well. Automotive companies must ensure that the introduction of XP does not reduce efficiency or lead to miscommunication among teams.

The Future of XP in Automotive

As automotive companies increasingly rely on software and technology in their vehicles, XP’s Agile framework will play an essential role in the industry’s future.

Trends in Agile Adoption

More automotive companies are adopting Agile frameworks like XP to enhance collaboration, improve product quality, and respond to changing customer demands. As the industry becomes more software-centric, the need for flexible, iterative development will only increase.

Role of Real-Time Updates and Adaptive Design

XP’s focus on real-time updates and adaptive design makes it ideal for the automotive industry, where rapid technological changes and evolving customer preferences require continuous updates. By integrating XP, automotive companies can ensure their products remain cutting-edge.

The Shift Towards a Software-Centered Future

The automotive sector is moving towards a future where software plays an increasingly central role in vehicle functionality, from autonomous driving to in-vehicle entertainment systems. XP, with its emphasis on rapid feedback and continuous improvement, is the perfect fit for this software-centered future.

Unlocking the Full Potential of Extreme Programming in Automotive

Extreme Programming offers automotive companies a proven framework for enhancing collaboration, improving product quality, and maintaining agility in a fast-moving industry. By implementing XP, manufacturers can stay responsive to customer needs, deliver high-quality products faster, and continuously improve their offerings.

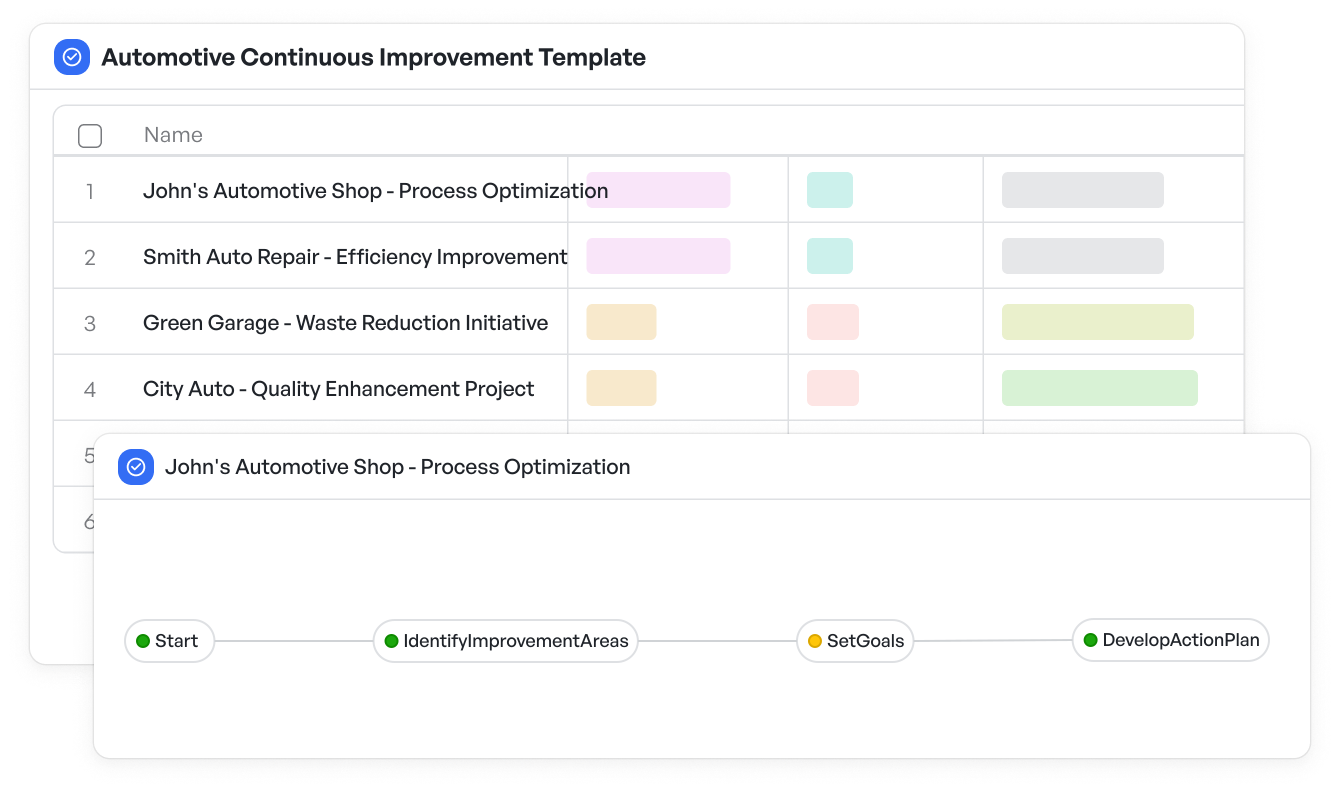

With Meegle’s tools, automotive companies can improve team collaboration, streamline development processes, and deliver high-quality products.

Start implementing XP in your automotive development processes.

The world’s #1 visualized project management tool

Powered by the next gen visual workflow engineRead More

Check All BlogsStart creating impactful work today