How to Implement Extreme Programming in Manufacturing

Extreme Programming (XP), primarily known for its role in Agile software development, has extended its reach into other sectors, including manufacturing. With its emphasis on collaboration, feedback, and adaptability, XP can enhance manufacturing processes, creating efficiencies and fostering continuous improvement.

In this article, we’ll explore how XP's core principles and practices can be applied in manufacturing environments, the benefits it brings, and how Meegle's tools can support this transition.

Understanding Extreme Programming (XP)

Extreme Programming (XP) is an Agile development methodology designed to improve software quality and responsiveness to customer needs. Its core values—communication, simplicity, feedback, courage, and respect—make it adaptable to industries beyond software development. In manufacturing, XP’s emphasis on iterative improvements, team collaboration, and rapid feedback aligns well with the fast-paced nature of production environments.

Core Values and Principles of XP

XP is founded on five core values that shape the way teams collaborate, innovate, and improve. These values can be applied in manufacturing to foster a culture of continuous improvement:

- Simplicity : Focusing on the simplest solutions minimizes waste and complexity.

- Communication : Ensuring clear and continuous communication helps resolve issues and align team goals.

- Feedback : Constant feedback helps to quickly identify inefficiencies and make improvements.

- Courage : Teams have the courage to experiment and make changes to processes when needed.

- Respect : All team members are valued and respected, promoting a cooperative environment.

XP also relies on several principles that prioritize iterative development, embracing change, and maintaining a sustainable pace—all of which can be valuable in the manufacturing context.

Manufacturing Project Plan Template

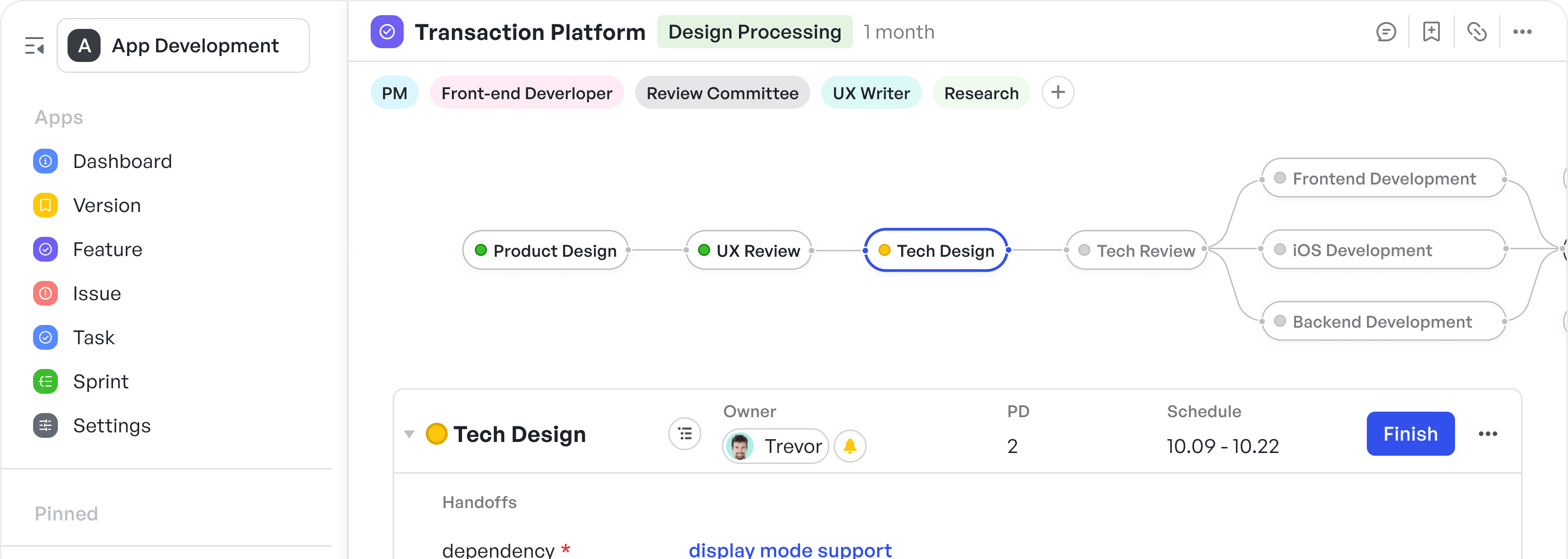

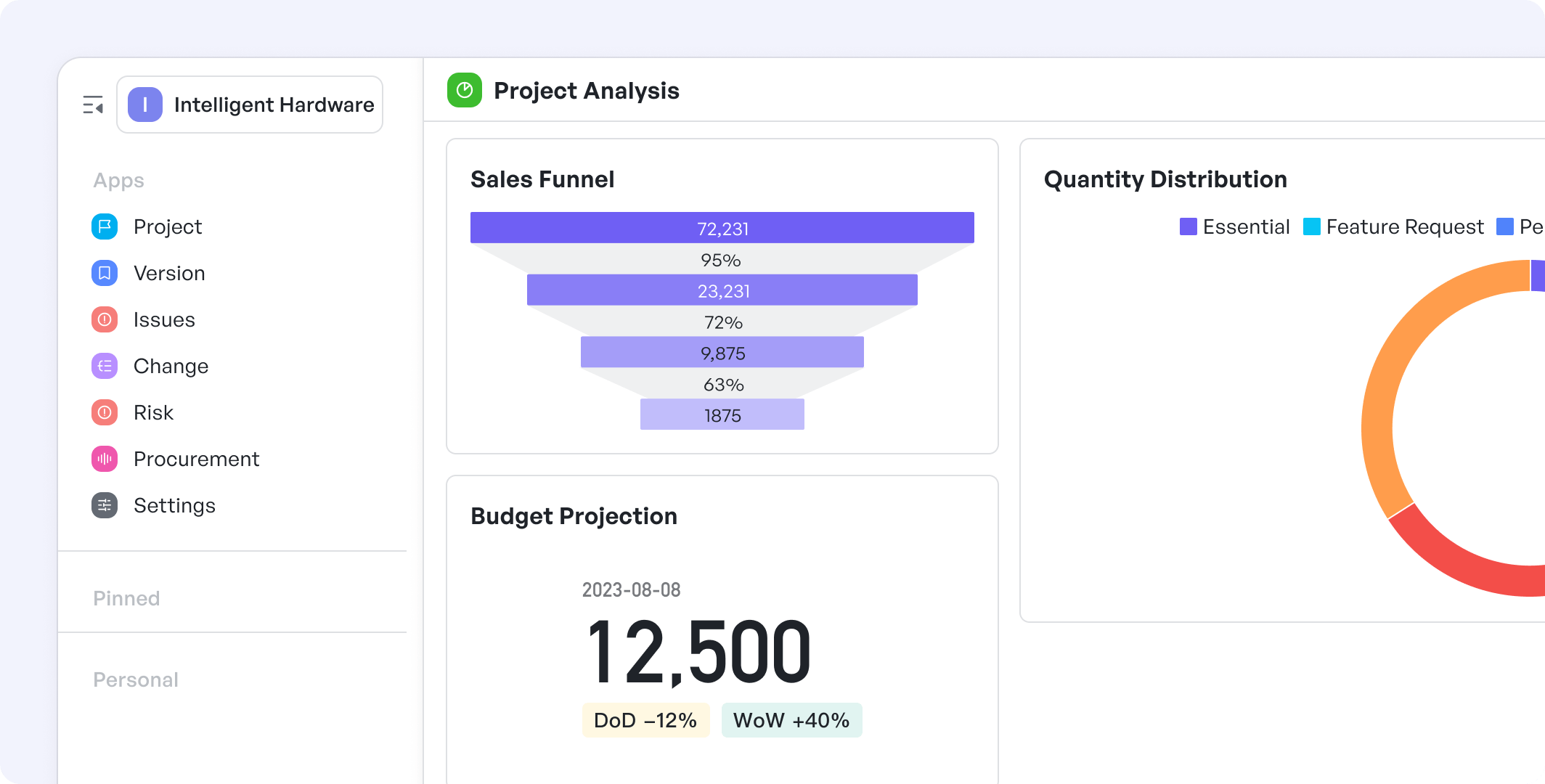

Meegle has a comprehensive manufacturing project management template designed for seamless planning, process optimization, and task management. Use Meegle’s templates to improve productivity, reduce delays, and streamline manufacturing workflows.

Jumpstart Your Projects with Top-tier Templates!

Primary Practices of XP

XP is structured around several practices that drive its core principles. These include pair programming, test-driven development, and continuous integration—all of which can enhance collaboration and efficiency in a manufacturing setting.

Key Practices Influencing Manufacturing

XP’s practices influence various stages of manufacturing processes. Here's how they can be adapted for better results:

Pair Programming

In XP, pair programming involves two developers working together on the same code. Similarly, in manufacturing, this could translate into collaborative problem-solving where two operators or teams work together to optimize production processes or troubleshoot issues.

Test-Driven Development

In software development, test-driven development (TDD) involves writing tests before code. In manufacturing, this can be equated with setting up performance benchmarks or quality control tests before producing goods, ensuring that everything meets set standards from the start.

Continuous Integration

In manufacturing, continuous integration can be seen as the process of integrating new equipment, materials, or processes regularly. This practice ensures that there are no bottlenecks in production and that improvements are continuously implemented without disrupting the workflow.

Swarming and Collaborative Problem-Solving

XP encourages collaborative problem-solving through practices like swarming—when the entire team works together to solve a problem quickly. In manufacturing, this can be adopted by encouraging cross-functional teams to address challenges as they arise, whether it's equipment failure or production delays.

Read more: How to Implement Kanban in Manufacturing

Integrating XP with Manufacturing

To fully realize the benefits of XP in manufacturing, organizations must integrate it with existing workflows. Here’s how XP can complement traditional manufacturing methods:

Synergy with Scrum

XP and Scrum share similar values, particularly when it comes to iterative development and continuous improvement. Combining XP with Scrum allows manufacturers to manage production in short, iterative cycles, gather feedback, and continuously improve processes.

Object-Oriented Architecture for Modularity

In software, XP uses object-oriented architecture to ensure code modularity. In manufacturing, this principle translates to designing modular systems where parts or processes can be swapped or updated without disrupting the entire system. This allows manufacturers to remain flexible and adaptable.

Implementing Small Releases

XP encourages small, incremental releases to gather feedback quickly. In manufacturing, this can mean rolling out small production batches for testing, ensuring any issues are addressed early without risking large-scale production failures.

Maintaining Simplicity in Design

Simplicity in design is a cornerstone of XP. In manufacturing, this practice translates into creating simple, efficient designs that reduce unnecessary complexity in production lines and help minimize errors, rework, and waste.

Download the Manufacturing Process Improvement Template for free!

Benefits of Adopting XP in Manufacturing

Implementing XP in manufacturing can provide numerous benefits that directly impact efficiency, quality, and team dynamics.

1. Enhancing Efficiency and Adaptability

XP’s emphasis on continuous feedback and small, incremental changes leads to more efficient processes. Manufacturers can quickly adapt to new challenges and requirements, maintaining high levels of productivity without sacrificing quality.

2. Ensuring High-Quality Outputs

With practices like test-driven development and continuous integration, XP ensures that quality is built into every step of the production process. By focusing on quality from the outset, manufacturers can avoid costly defects and ensure consistent output.

3. Rapid Feedback Loops and Improvements

XP’s quick feedback loops help teams identify and correct issues early. In manufacturing, this means less time spent on error correction and more time spent on innovation and improvement, keeping production lines running smoothly.

Challenges and Solutions of XP in Manufacturing

While XP offers many benefits, manufacturers may face challenges in implementation. Here’s how to address some common obstacles:

1. Addressing Extreme Problems

Manufacturing environments can be complex, with varying variables that make implementing XP challenging. Using Meegle’s templates and glossary pages, manufacturers can better understand XP practices and integrate them into their operations without causing disruption.

2. Providing Extreme Solutions

Implementing XP solutions requires strong leadership and commitment. For manufacturers, this might involve training teams on XP principles or finding the right balance between Agile practices and traditional manufacturing systems.

Unlocking the Full Potential of Extreme Programming in Manufacturing

Extreme Programming offers manufacturers a new way to improve collaboration, streamline production, and maintain high-quality outputs. By embracing XP, manufacturers can work more efficiently, adapt quickly to changing demands, and continuously improve their processes.

Meegle supports manufacturing teams in implementing XP by providing collaborative tools and templates designed to integrate Agile practices into everyday workflows.

The world’s #1 visualized project management tool

Powered by the next gen visual workflow engineRead More

Check All BlogsStart creating impactful work today