How to Implement Test-Driven Development in Manufacturing: Optimizing Processes for Success

In the fast-paced world of manufacturing, where quality and efficiency are paramount, companies are constantly seeking ways to streamline processes and improve outcomes. One method that has gained significant traction in various industries is Test-driven development (TDD).

While test-driven development is traditionally associated with software development, its principles can also be applied to manufacturing processes to ensure the highest quality and minimize errors.

In this blog post, we’ll explore how test-driven development can be used in manufacturing to optimize workflows, enhance product quality, and ultimately reduce production costs.

What is Test-Driven Development in Manufacturing?

Test-driven development is a software development methodology where tests are written before the actual code. The idea is simple: developers create a test case based on the expected outcome, write the code to pass the test, and then refactor the code to improve performance. The process is iterative and cyclical, ensuring that the final code meets the desired specifications without introducing bugs.

In the context of manufacturing, test-driven development involves a similar approach. Rather than waiting for a product or process to be complete before testing its functionality, the manufacturing team can identify potential issues or inefficiencies early in the production process, test solutions, and refine their approaches based on those results. This proactive testing approach minimizes and manages risk while optimizing the production process at every stage.

5 Reasons Why Test-Driven Development in Manufacturing Matters

In manufacturing, traditional quality control often occurs at the end of the production cycle, which can result in costly delays and rework. With test-driven development, issues are caught early, allowing manufacturers to make adjustments before they become costly problems.

Here are some reasons why test-driven development is valuable in manufacturing:

1. Faster Feedback Loops

By testing prototypes and processes early, manufacturers can establish a feedback loop to identify flaws or inefficiencies before they scale, thereby reducing the time spent on rework and improving overall production efficiency.

2. Improved Product Quality

Test-driven development ensures that every step of the manufacturing process is optimized for quality.

With continuous testing during both development and production stages, manufacturers can ensure each component meets the desired standards, leading to fewer defects and higher-quality products.

3. Cost Reduction

Implementing test-driven development in manufacturing helps identify and address inefficiencies early, reducing waste and preventing the need for costly fixes later in the process. This approach results in significant cost savings over time.

You may be interested in: 👉Cost reduction strategies in manufacturing

4. Increased Collaboration

Test-driven development encourages cross-functional collaboration. By involving all team members early on—engineers, designers, and quality control experts—manufacturers can create more robust processes that work efficiently across all departments.

5. Continuous Improvement

Test-driven development supports a culture of continuous improvement. As each test provides valuable data, manufacturers can constantly refine their processes, enhancing overall productivity and adapting to changes in market demand or technology.

7 Steps to Implement Test-Driven Development in Manufacturing

Implementing test-driven development in manufacturing requires a shift in mindset and a willingness to embrace testing at every stage of the production process. Here are some steps manufacturers can take to integrate test-driven development into their operations:

1. Define Clear Objectives

Before introducing test-driven development, manufacturers should define clear objectives for their processes. What outcomes do they want to achieve? Are they focused on improving product quality, increasing throughput, or reducing waste?

Clear goals will help guide the testing process and ensure that each test is aligned with the overall manufacturing objectives.

You may be interested in: 👉Lack of clear objectives

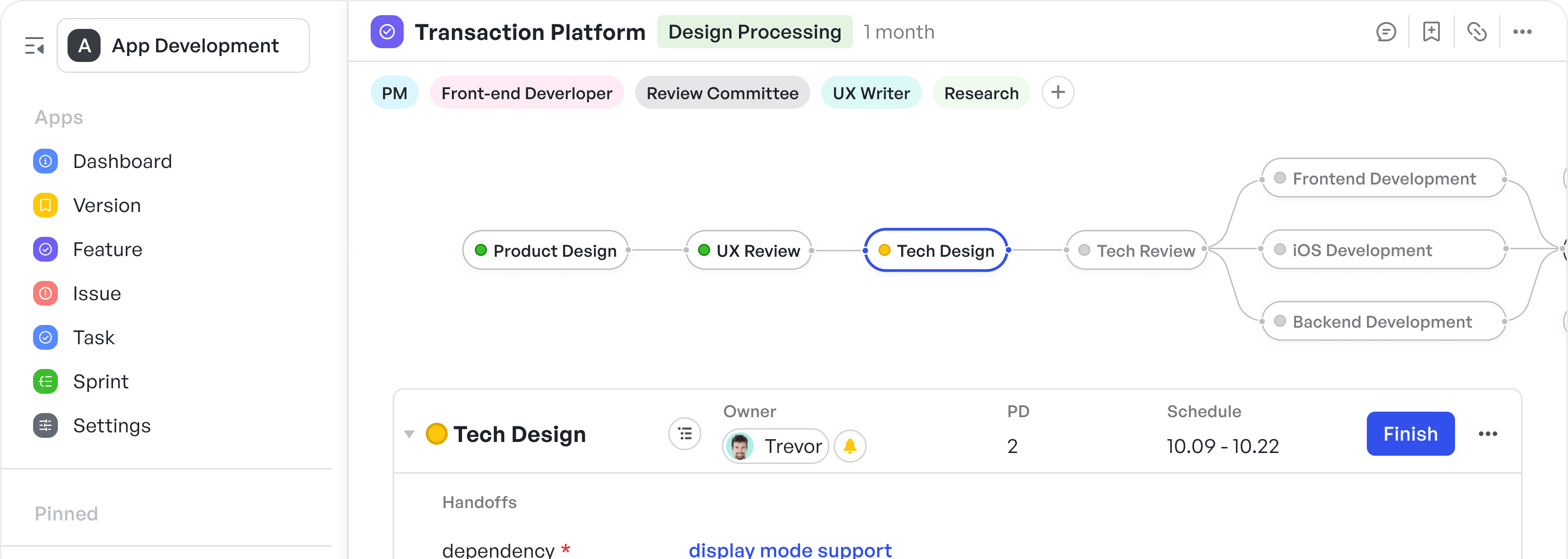

2. Map Out the Workflow

Creating a detailed value stream map of the manufacturing process is essential for identifying potential areas where tests can be introduced. This workflow mapping helps highlight critical steps in production, allowing manufacturers to pinpoint where issues are most likely to arise.

You can enhance this process by using tools like the value stream mapping workflow template, which visualizes the entire flow and helps identify bottlenecks and inefficiencies. This approach ensures continuous improvement by aligning team efforts with targeted process improvements.

Value stream mapping workflow template to identify and eliminate inefficiencies

Value stream mapping workflow template to identify and eliminate inefficiencies3. Write Test Cases for Each Step

Once the workflow is mapped out, manufacturers can start writing test cases for each stage of production. These test cases should be designed to validate that each step of the process is functioning as intended.

For example, a test case for a machining process might verify that a part is being cut to the correct dimensions within tolerance.

4. Iterate and Refine

As with software development, test-driven development in manufacturing is an iterative process. After each test, manufacturers should assess the results, make any necessary adjustments, and retest the process.

This continuous loop of testing and refinement leads to improvements at every stage of production.

5. Incorporate Automation

Automating the testing process can significantly speed up the workflow. Automation tools can be used to run tests in real-time, collect data, and trigger alerts if any issues are detected.

This allows manufacturers to monitor production continuously and make adjustments on the fly.

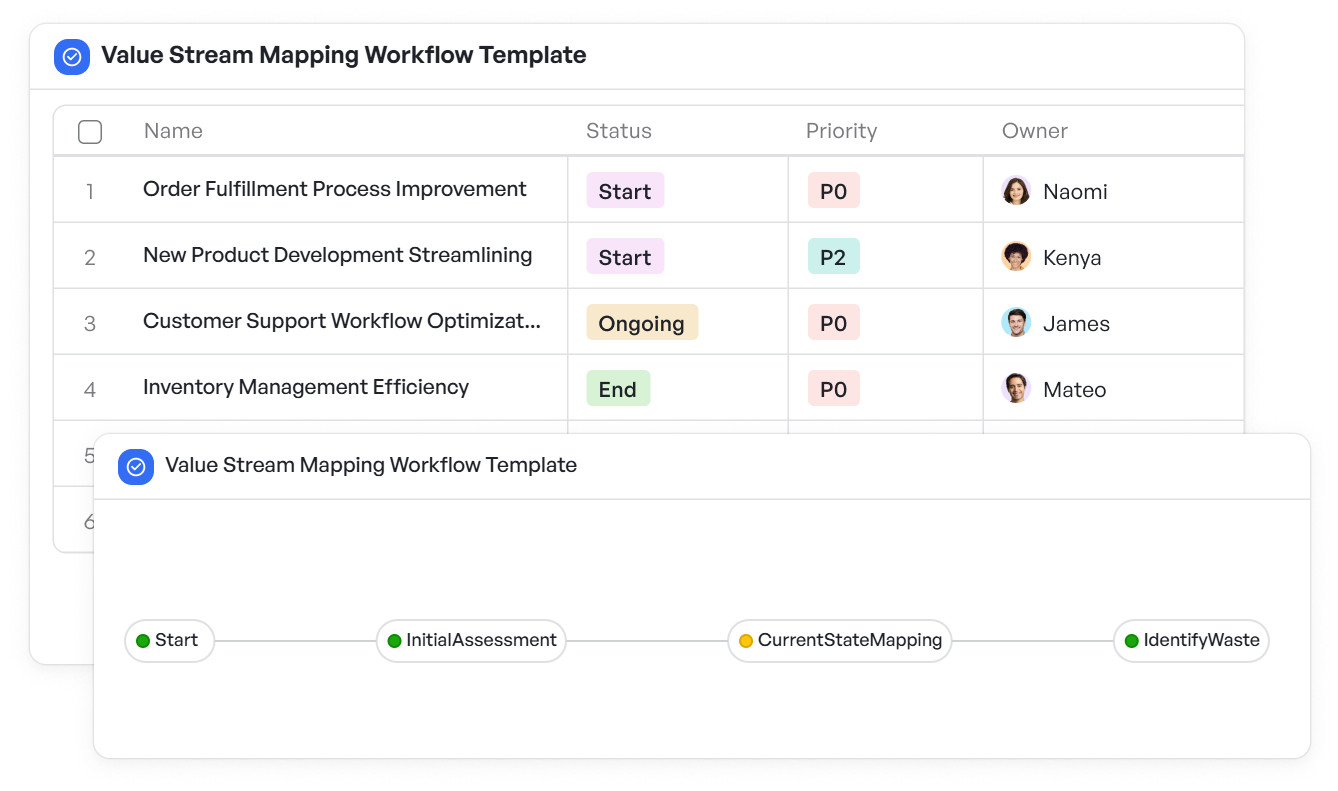

6. Train the Team

For test-driven development to be effective, the entire team needs to understand its principles and how to implement them. Manufacturers should invest in structured training programs that teach staff how to write and execute test cases, analyze results, and make improvements.

Using a comprehensive technical training program outline, teams can ensure that all employees are aligned with the objectives of implementing test-driven development, enhancing productivity and reducing errors in the long run.

Structure training programs that teach your team how to write, execute, and analyze test cases

Structure training programs that teach your team how to write, execute, and analyze test cases7. Monitor and Analyze Results

After the tests have been run, it’s essential to monitor the results closely. Collecting data on the outcomes of each test allows manufacturers to identify patterns, detect recurring issues, and track the effectiveness of changes made over time.

This data-driven decision-making approach enhances decision-making and enables manufacturers to continuously improve their processes.

The Benefits of Test-Driven Development in Manufacturing

Test-driven development offers a proactive approach to improving manufacturing processes by focusing on continuous testing and refinement, leading to numerous operational benefits.

Reduced Risk and Increased Confidence

By identifying potential issues early, manufacturers can prevent expensive rework and avoid delays in production with proper production planning.

This approach also provides manufacturers with greater confidence in their processes, knowing that each step has been rigorously tested and refined.

Enhanced Product Consistency

One of the key advantages of test-driven development is its ability to ensure consistency. By continuously testing each step in the manufacturing process, manufacturers can achieve more consistent results, leading to fewer defects and better-quality products.

Improved Communication Across Teams

Test-driven development fosters collaboration between different departments, ensuring that everyone is aligned on the goals and standards for the production process. As a result, communication improves, which leads to more efficient workflows and faster problem-solving.

Better Resource Utilization

With test-driven development, manufacturers can optimize their resources more effectively. By identifying inefficiencies early in the process, manufacturers can adjust their workflows to minimize waste and maximize the use of materials, labor, and equipment.

Achieve Excellence with Test-Driven Development in Manufacturing

Test-driven development offers manufacturers a powerful tool to enhance their processes, reduce defects, and improve overall product quality. By embracing a proactive approach to testing and refining processes, manufacturers can achieve greater efficiency, reduce waste, and maintain high standards of quality throughout the production cycle.

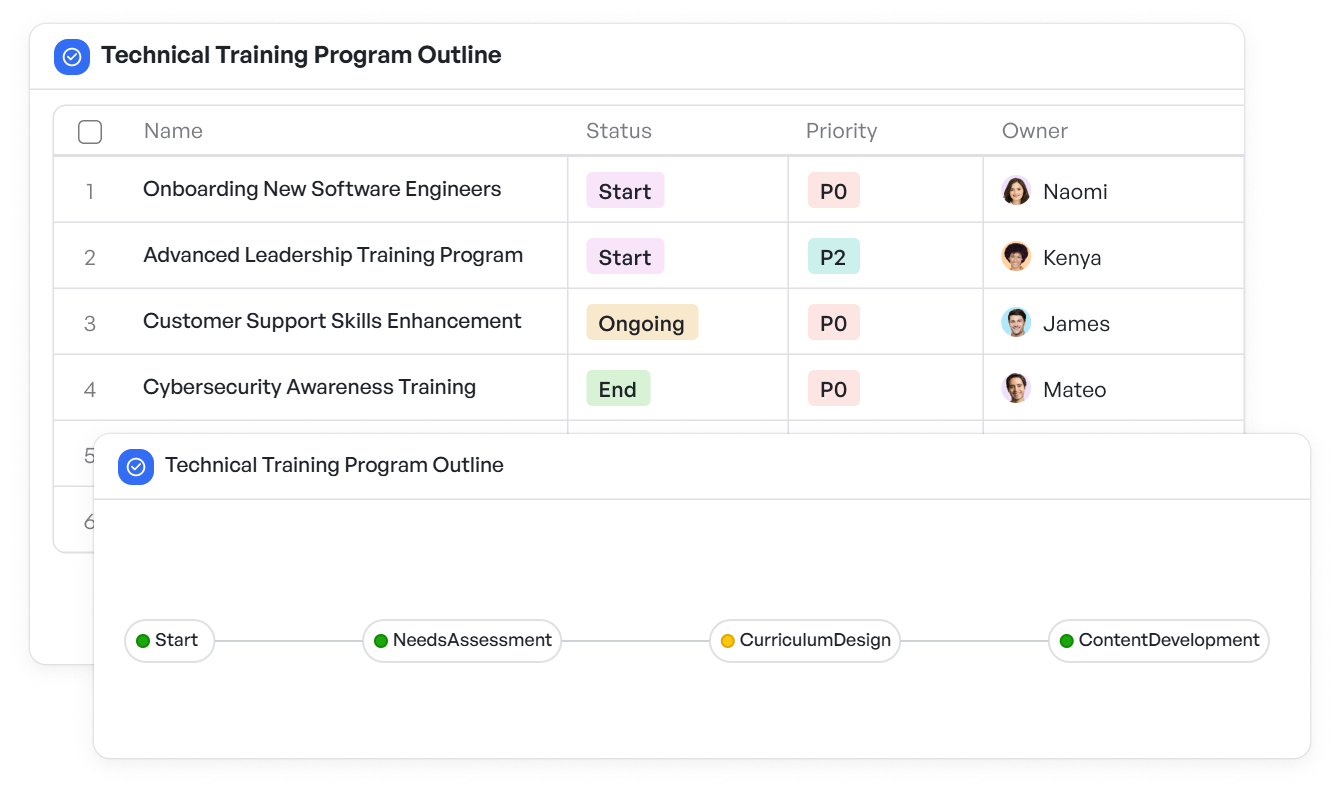

Incorporating test-driven development into manufacturing operations allows teams to visualize workflows and collaborate seamlessly, making it easier to stay on track with complex projects.

With flexible tools that support complex workflows, manufacturers can implement test-driven development at scale and see continuous improvement over time.

Accelerate test-driven development in manufacturing by turning complex workflows into a visual, collaborative process.

The world’s #1 visualized project management tool

Powered by the next gen visual workflow engineRead More

Check All BlogsStart creating impactful work today