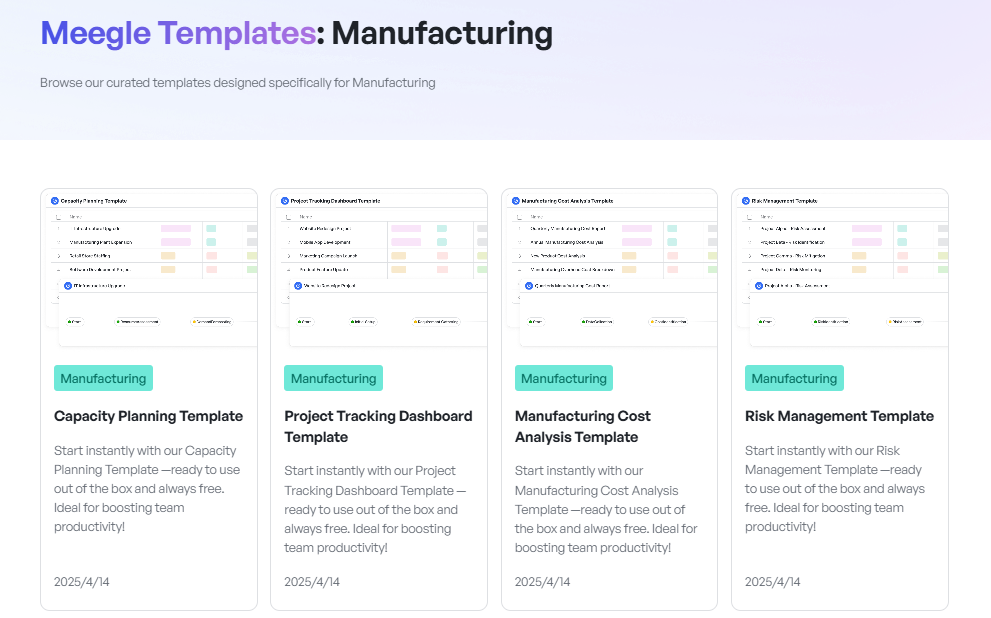

How To Implement Crystal In Manufacturing: Driving Clarity And Agility On The Production Floor

Manufacturing organizations today face a unique blend of challenges: demand volatility, supply chain uncertainties, lean expectations, and increasingly complex production environments. In such settings, software teams supporting manufacturing operations need agile methods that promote visibility, adaptability, and human-centric collaboration.

Crystal, an Agile methodology originally shaped for software development, is being adopted across diverse domains, including manufacturing, because of its flexible, people-first approach.

The following sections explore this shift in more detail.

What is Crystal Methodology?

Crystal is a family of Agile methodologies created by Alistair Cockburn. Each "crystal" method (crystal Clear, crystal Yellow, crystal Orange, etc.) is suited to different team sizes and project complexities.

The foundational idea is that “one size does not” fit all. Crystal tailors the Agile process to fit the context, based on communication needs, team dynamics, and criticality of the project.

In manufacturing, where cross-functional teams often operate with different tools and terminologies, crystal’s adaptive, context-based approach fits well.

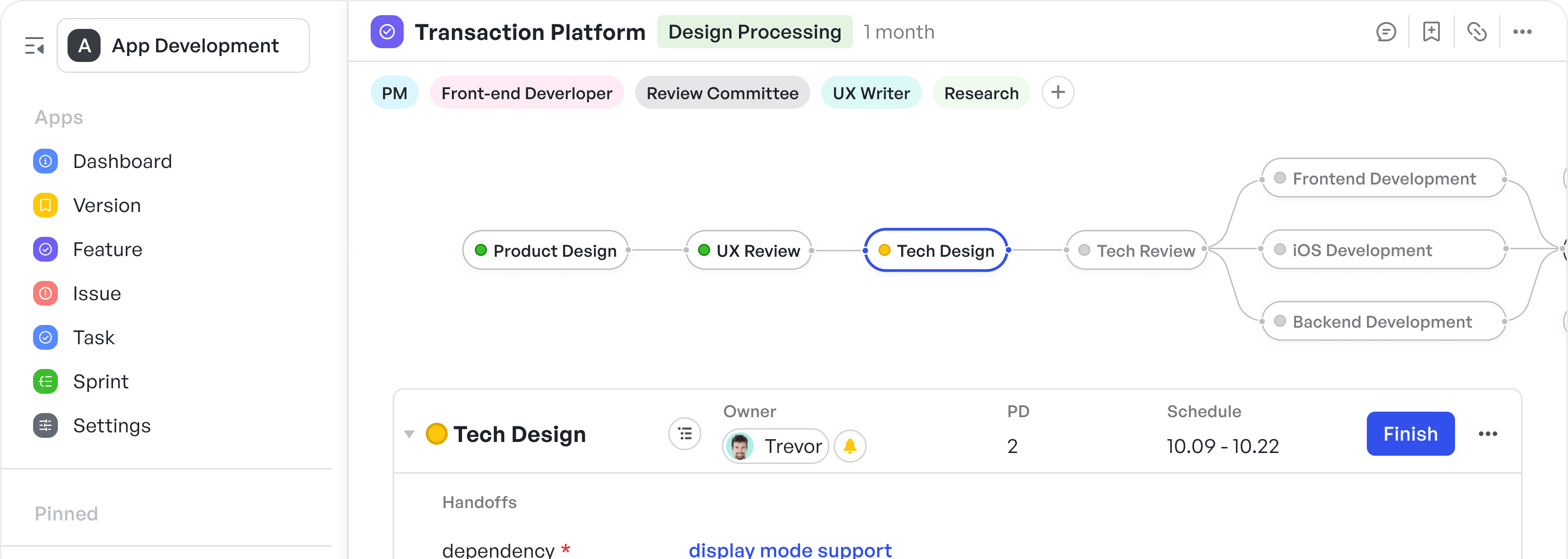

Meegle's Context-aware prompt design framework

Meegle's Context-aware prompt design frameworkWhy Manufacturing Teams Are Turning to Crystal for Agile Visual Workflows

Although Agile is commonly linked to software development, manufacturing has embraced similar principles for decades through approaches like lean, Six Sigma, and Kaizen by emphasizing continuous improvement, iterative testing, and waste reduction.

But traditional manufacturing process tools tend to be rigid. Agile methods like crystal introduce:

- Frequent delivery cycles (even for internal tools or documentation)

- Lightweight documentation without sacrificing traceability

- Clear ownership and communication models across distributed teams

These benefits make crystal an attractive Agile variant for modern manufacturing teams building digital systems, process automation layers, or supporting plant operations through internal apps.

You might be interested in: Hybrid vs traditional PM

How Crystal Aligns with Manufacturing Realities

Here’s how crystal methodology supports the evolving needs of manufacturing software and operations teams:

1. Adaptability Based on Team Size

Crystal scales its practices according to team size and project sensitivity. Manufacturing often has varied team setups—from small automation squads to large enterprise resource planning (ERP) implementation groups.

Crystal Yellow may suit a 10-person manufacturing execution system (MES) tool development team, while crystal Orange could guide larger digital twin simulation projects.

2. Emphasis on People and Interaction

Manufacturing ecosystems involve engineers, designers, IT teams, operations, and quality control.

Crystal focuses on human-powered efficiency: structured collaboration, real conversations, and reducing communication silos.

For example, daily standups with production and software teams together foster alignment on automation scripts, dashboards, or sensor rollouts.

3. Deliver Early, Deliver Often

Crystal promotes early and frequent delivery of working software or outputs. In a manufacturing context, this might mean quickly releasing a dashboard prototype to the shop floor team, getting feedback, and refining it iteratively.

Such cadence accelerates internal adoption of tools, helping production teams feel included and heard.

4. Light but Effective Documentation

Crystal encourages documentation only to the extent it supports communication.

For manufacturing teams juggling SOPs, compliance, and audits, this is refreshing. Instead of over-engineering specifications, teams can focus on meaningful documentation: design intent, versioning, and basic release notes.

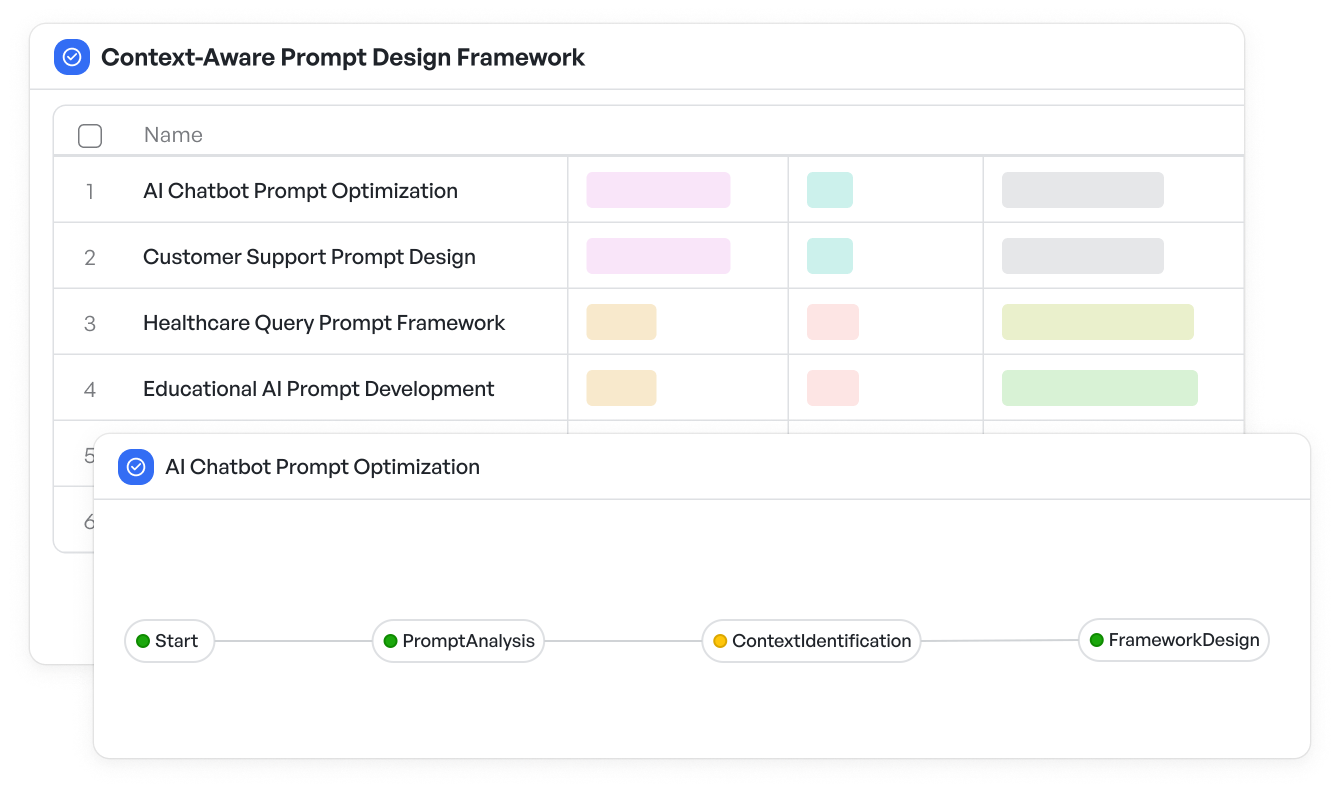

You might be interested in: Technical documentation synchronization template

You might be interested in: Technical documentation synchronization templateSuggested Read:👉Best Project Management Software for Manufacturing in 2025

Typical Use Cases for Crystal in Manufacturing

Here are a few ways crystal-driven practices benefit manufacturing teams:

Production Monitoring Dashboards

Using “crystal clear” methodology, a small digital team might co-develop an internal dashboard with operators, gathering weekly feedback to refine KPIs and UI elements.

Internal Tooling Development

A manufacturing execution team working on internal workflow automation (like raw material intake tracking or quality check workflows) can run crystal Orange with weekly demos to stakeholders from inventory, quality, and operations.

ERP Extension Projects

Adding new features to an ERP or integrating it with shop-floor devices is complex. Crystal’s tailored approach helps manage interdependencies, ensuring communication across IT, production, and vendor teams.

Common Roadblocks in Crystal Adoption for Manufacturing

While crystal is flexible, manufacturing teams should consider:

- Cultural readiness: Agile adoption often demands mindset shifts. Hierarchical organizations may need change agents.

- Tooling gaps: Agile methods rely on visibility. Traditional tools often miss that visual clarity.

- Cross-functional buy-in: Engineering, QA, and IT must collaborate openly, which can take time to build.

This is where a structured, visual workflow platform becomes essential.

Suggested Read:👉7 Best Visual Project management software 2025

Supporting Crystal with the Right Tools

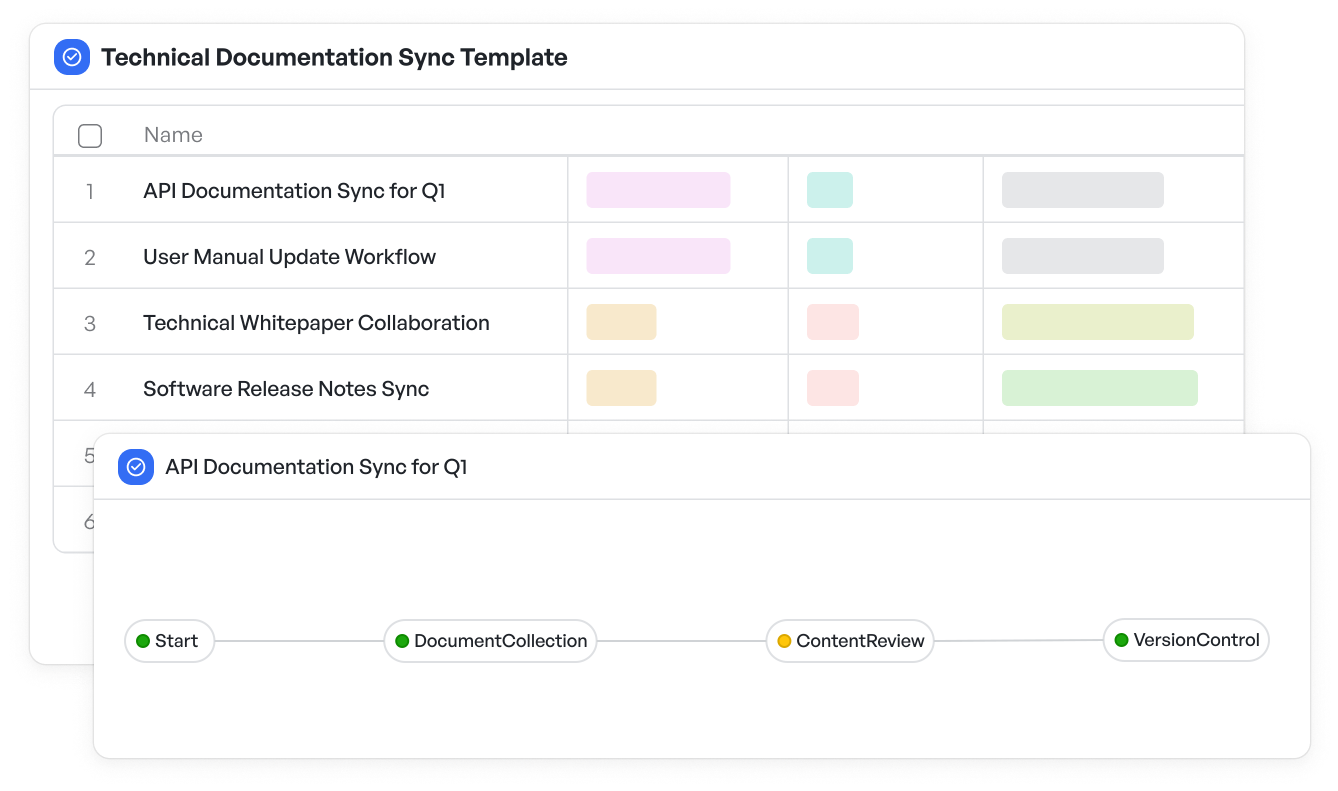

For manufacturing teams applying crystal, success often hinges on clarity:

- Who is doing what?

- What is the status of each work item?

- Where are we stuck?

A visualized workflow tool helps answer these questions quickly and consistently. Everyone sees the same information, minimizing misalignment.

Manufacturing software teams can also take advantage of ready-to-use templates that mirror operational realities—such as those designed for production planning, maintenance tracking, or resource scheduling.

You might be interested in: Manufacturing templates

You might be interested in: Manufacturing templatesTip:

If you're looking to apply crystal effectively in a manufacturing environment, pairing the methodology with the right tools can significantly improve clarity, accountability, and delivery speed.

Find the right workflows that fit complex manufacturing needs, without the overhead of learning a heavyweight platform.

Crystal in Manufacturing Enables Smarter Workflow Management

Software and operations teams in manufacturing deserve tools that match their pace and project complexity. By aligning crystal methodology with visual workflows, teams can reduce confusion, communicate better, and focus on delivery.

Clarity drives performance—Meegle delivers crystal-clear workflow execution for fast, flexible manufacturing

The world’s #1 visualized project management tool

Powered by the next gen visual workflow engineRead More

Check All BlogsStart creating impactful work today