How To Implement Lean In Automotive: Improve Efficiency And Cut Waste

The automotive industry operates under constant pressure to deliver high-quality products at speed while navigating supply chain disruptions, compliance demands, and cost pressures.

Amidst this complexity, automotive companies are adopting lean practices to reduce inefficiencies, enhance cross-functional collaboration, and accelerate delivery without compromising quality.

Lean has deep roots in the automotive industry, with its origins on the shop floors of automakers like Toyota. Over the years, its principles have extended beyond assembly lines into areas like product development, engineering, and software-driven vehicle systems.

For today’s automotive teams, Lean remains a practical, scalable approach to reducing inefficiencies while managing increasing complexity.

So how does lean apply to the automotive sector in 2025?

The Evolution of Lean in Automotive

Lean thinking in the automotive space began as a way to reduce waste and improve flow on the production line. Over time, it expanded to upstream processes like design, procurement, engineering, logistics, and aftermarket services.

Today, automotive organizations are adopting lean principles in areas such as:

- Vehicle Development: Accelerating prototype-to-production timelines

- Supply Chain Management: Reducing inventory buffers while maintaining flexibility

- Software Integration: Aligning cross-functional product teams to deliver better digital experiences

- Project Management: Replacing siloed processes with transparent, visual workflows.

By focusing on eliminating non-value-added activities, lean helps these teams stay focused, reduce rework, and respond faster to changes in market or compliance requirements.

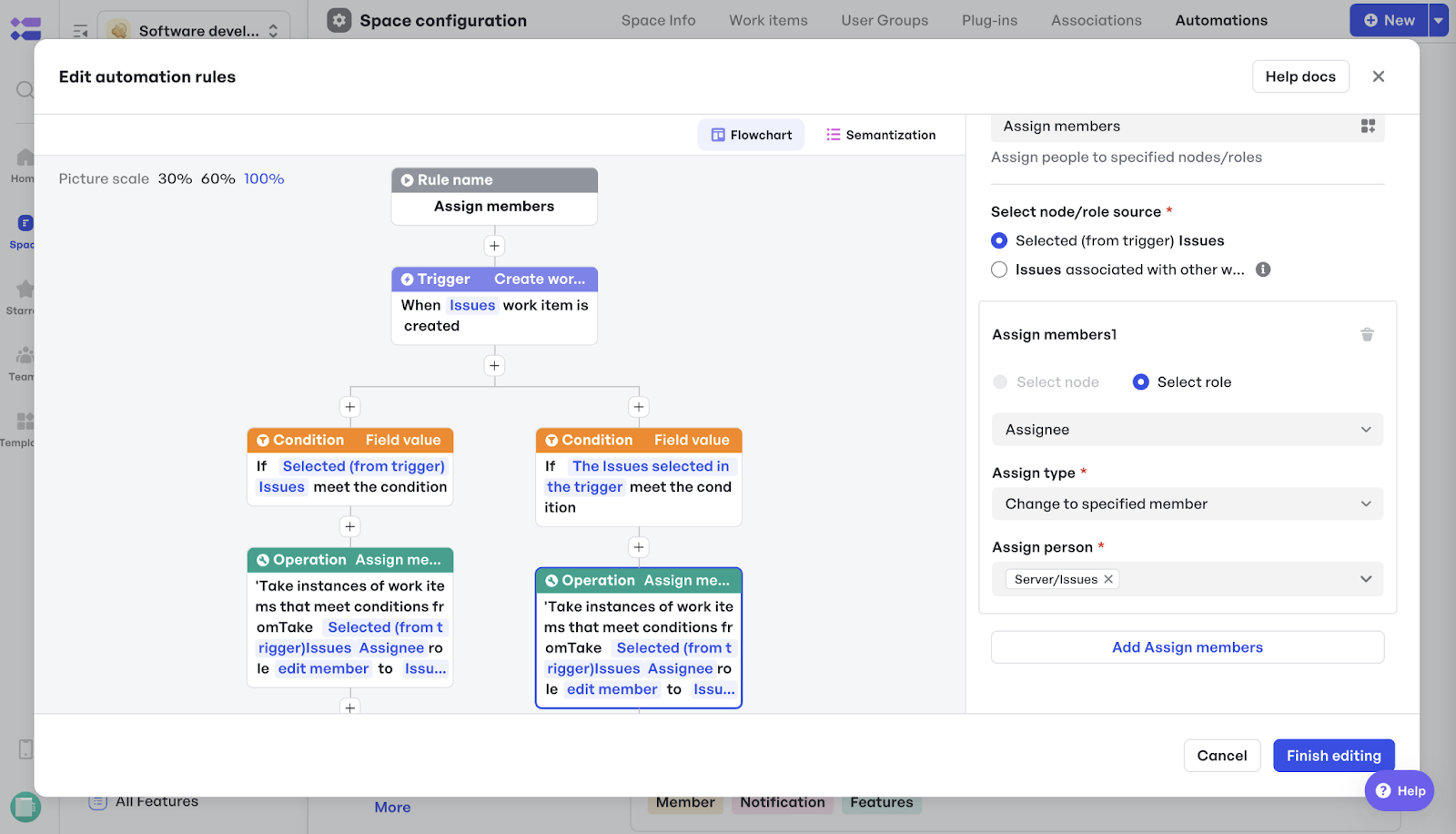

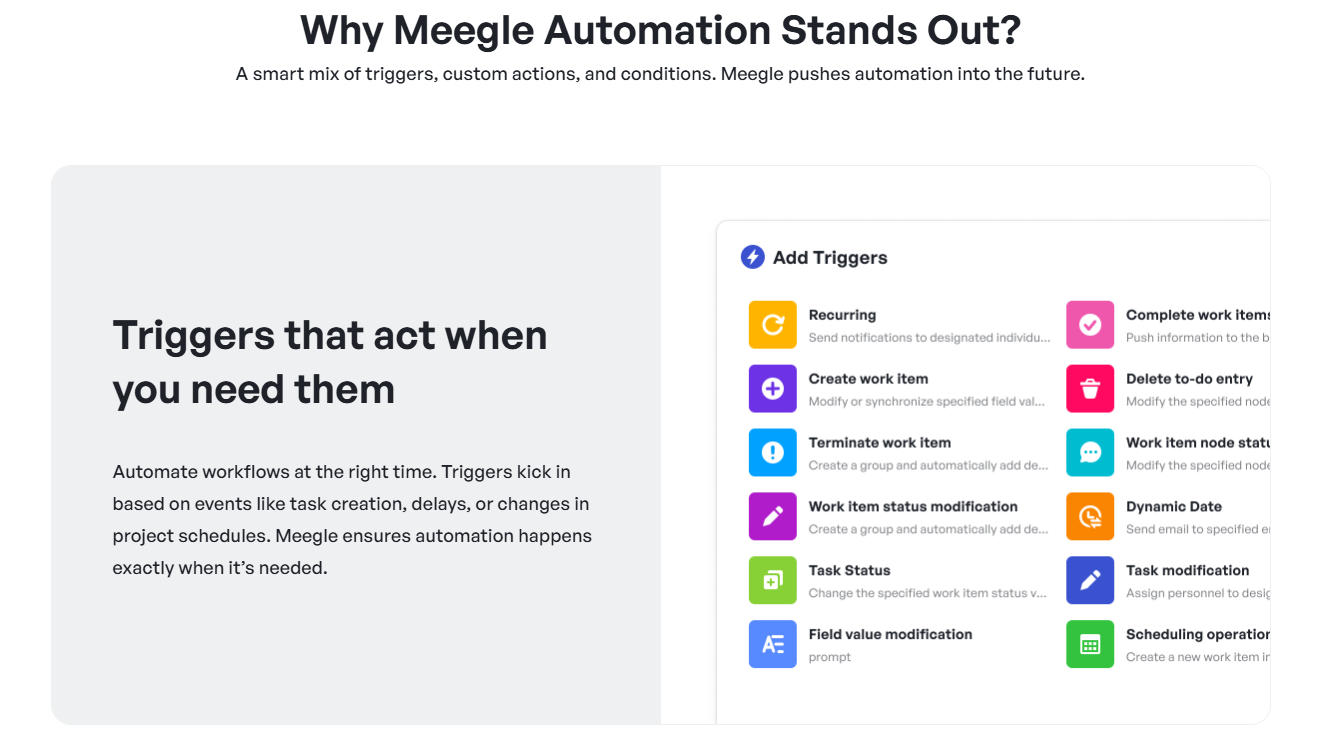

Automation in Meegle

Automation in MeegleCore Lean Principles for Automotive Organizations

Whether you're in an original equipment manufacturer (OEM), Tier 1 supplier, or software provider supporting the automotive sector, lean revolves around five core principles:

- Define Value: Understand what the end customer truly cares about and design every step to support it.

- Map the Value Stream: Identify all the steps in a process and distinguish between value-added and non-value-added activities.

- Create Flow: Ensure that value-adding steps occur in a smooth, uninterrupted sequence.

- Establish Pull: Produce only what is needed when it is needed, minimizing overproduction.

- Continuous Improvement: Constantly evaluate and improve processes to reduce waste and boost performance.

These principles are as applicable in software-led automotive projects as they are on the factory floor.

Where Automotive Teams Hit Roadblocks

Even with a lean mindset, many automotive teams struggle with execution. Common friction points include:

- Siloed departments using disconnected tools

- Poor visibility into project ownership and timelines

- Difficulty tracking multiple moving parts across engineering, procurement, and production

- Delays caused by redundant approvals and rework

This is where visual workflows become critical. They allow teams to see the entire process—from concept to delivery—on a single canvas. With the right platform, teams can coordinate work, flag blockers early, and adapt faster.

Meegle for automation

Meegle for automationWhy Visual Workflows Accelerate Lean Adoption

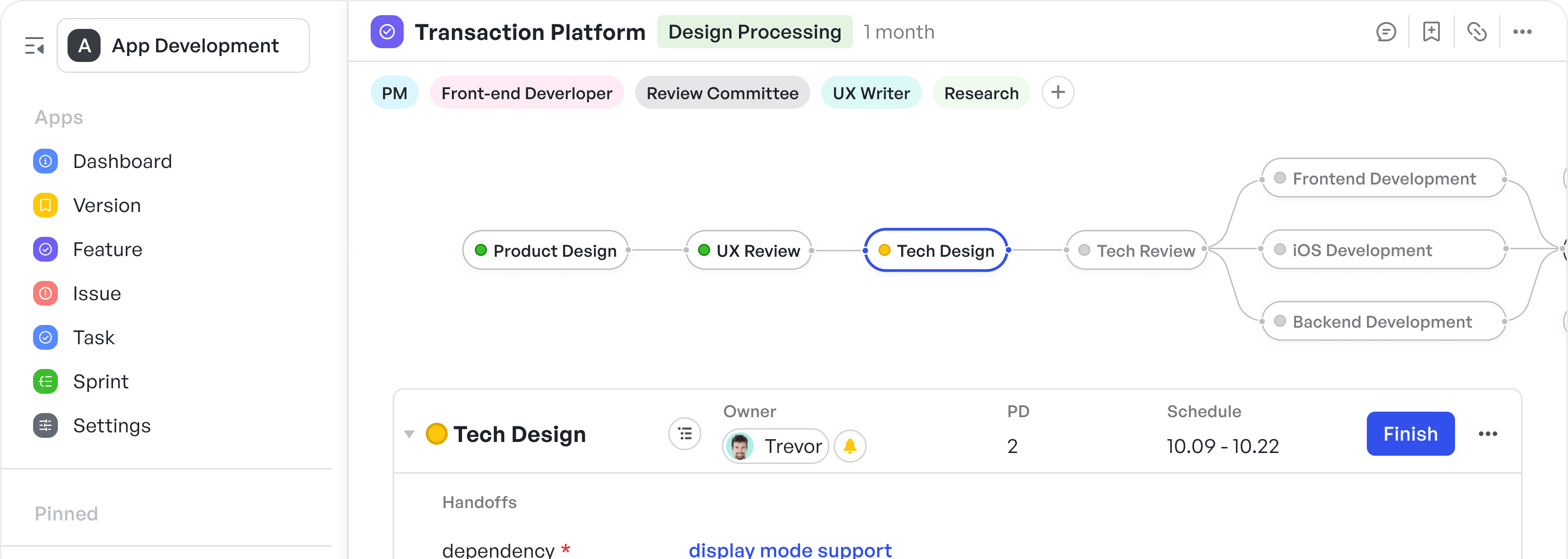

Automotive projects often involve dozens of cross-functional roles, especially as software becomes a larger part of the vehicle experience. A visual workflow provides the clarity needed to:

- Track dependencies across departments

- Understand current progress and next steps

- Know who is responsible for each task

- Spot delays before they escalate

- Keep leadership aligned without endless meetings

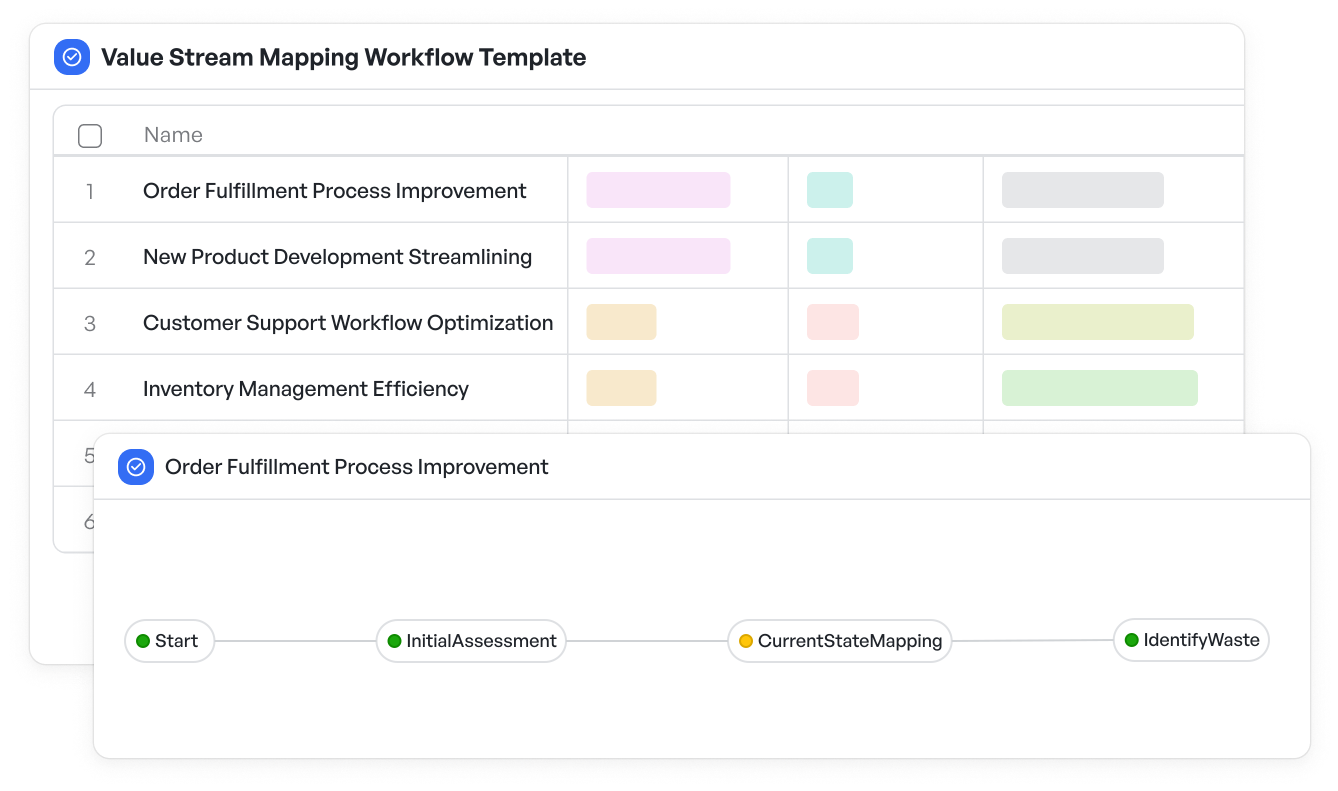

This can be supported by configurable, visual templates for project workflows—making it easier to implement lean without adding complexity.

For example, a value stream mapping template helps project managers and engineers align on bottlenecks and prioritize improvements.

Suggested read: 👉7 Best visual project management software for 2025

Meegle's Value stream mapping template

Meegle's Value stream mapping templateEnhancing Lean with Integration Tools

Lean workflows gain additional power when connected seamlessly with other enterprise systems. In automotive, data flows between design software, manufacturing execution systems, procurement platforms, and quality control tools.

Integration tools ensure that information moves automatically across these systems, reducing manual entry, minimizing errors, and accelerating decision-making.

By connecting visual workflows with your existing tech stack, teams can maintain a single source of truth, enabling faster response to issues and smoother collaboration across departments.

Platforms like Meegle support integrations that help unify your automotive operations, making Lean adoption more effective and scalable.

All your tools, tasks, and teamwork are streamlined in one visual workspace.

All your tools, tasks, and teamwork are streamlined in one visual workspace.Lean Use Cases in Modern Automotive Workflows

1. Lean Product Development

Teams working on vehicle software, infotainment systems, or EV battery management need structured ways to iterate and ship quickly. Lean workflows help minimize waste by:

- Reducing design rework through feedback loops

- Improving cross-team communication

- Prioritizing work that directly delivers customer value.

Suggested Read:👉Best product development software picks for 2025

Meegle's Product development plan template

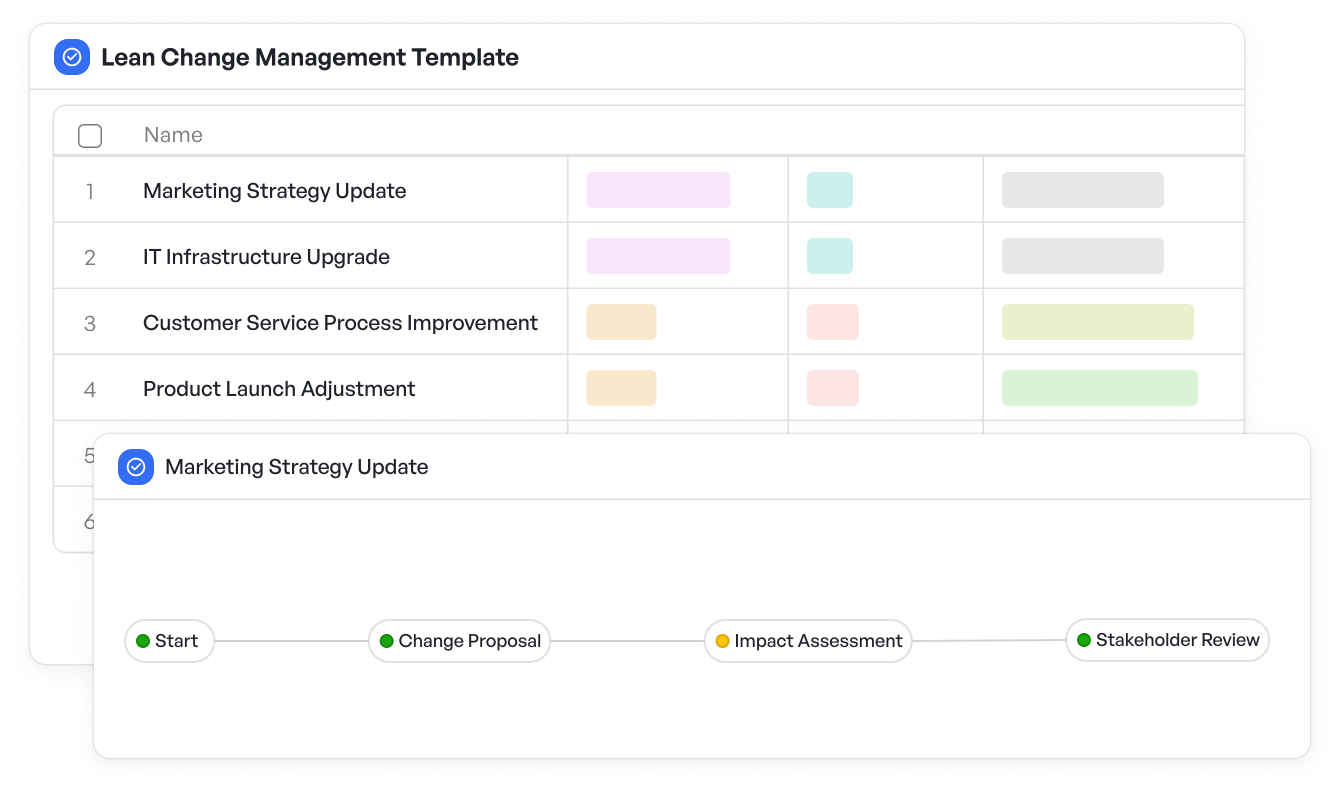

Meegle's Product development plan template2. Engineering Change Management

Tracking and implementing change requests across supply, design, and compliance teams can slow down progress. A lean-based, visual process helps stakeholders:

- Assess impact quickly

- Coordinate approvals

- Close the loop faster across systems

Lean change management template

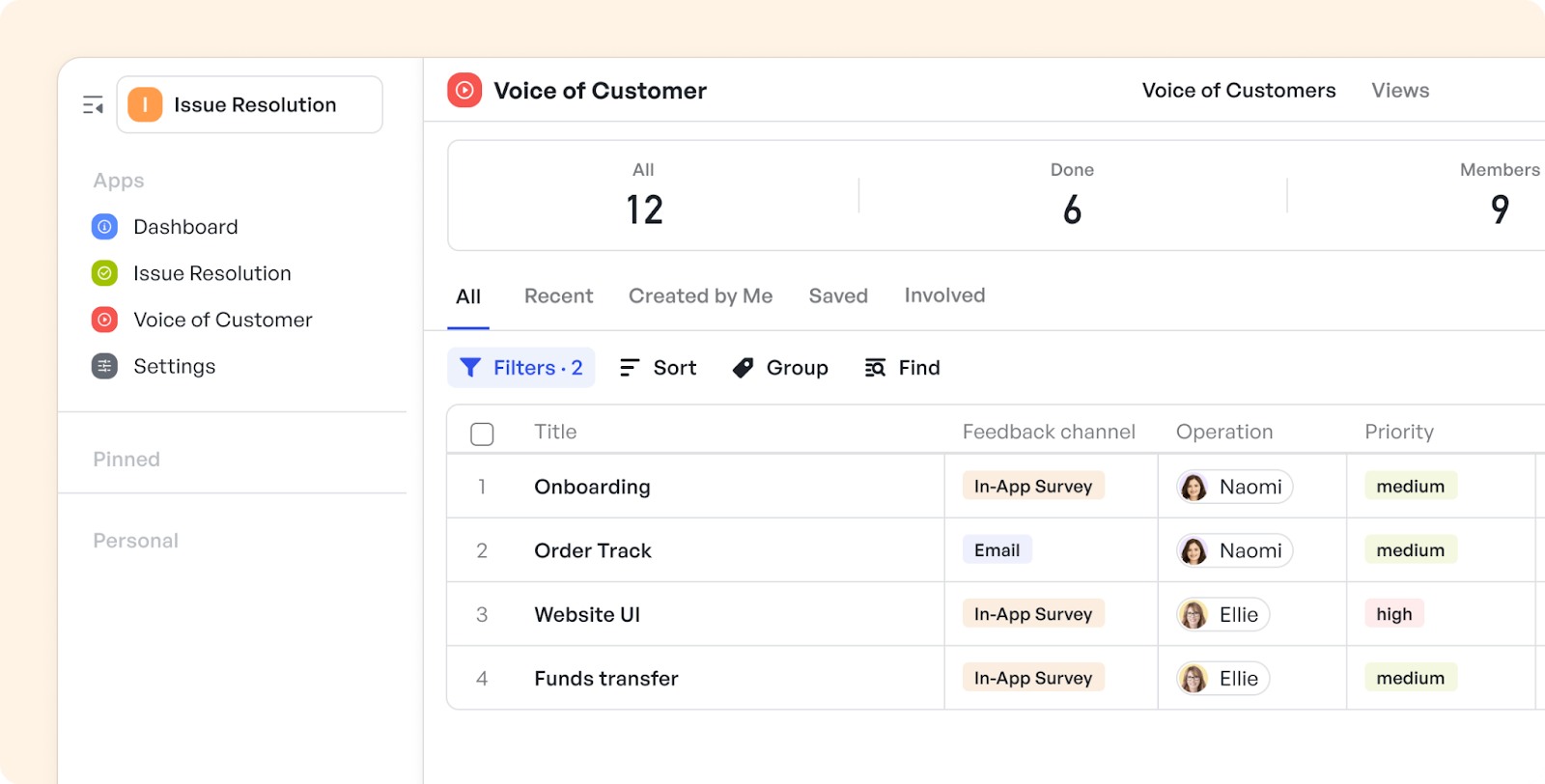

Lean change management template3. After-Sales Services and Issue Resolution

Handling technical recalls or service requests involves coordination across QA, service, and engineering. Lean tools make it easier to:

- Capture root cause data

- Assign ownership clearly

- Monitor resolution progress with full visibility

Issue resolution template

Issue resolution templateCulture Shift: Sustaining Lean Beyond the Pilot Phase

The shift to lean isn’t just procedural—it requires a mindset change. Teams need to:

- Be willing to share work openly

- Commit to continuous learning

- Reflect regularly on what’s not working

Leadership must also support a culture of collaboration and experimentation. With the right software platform, such behaviors become easier to maintain.

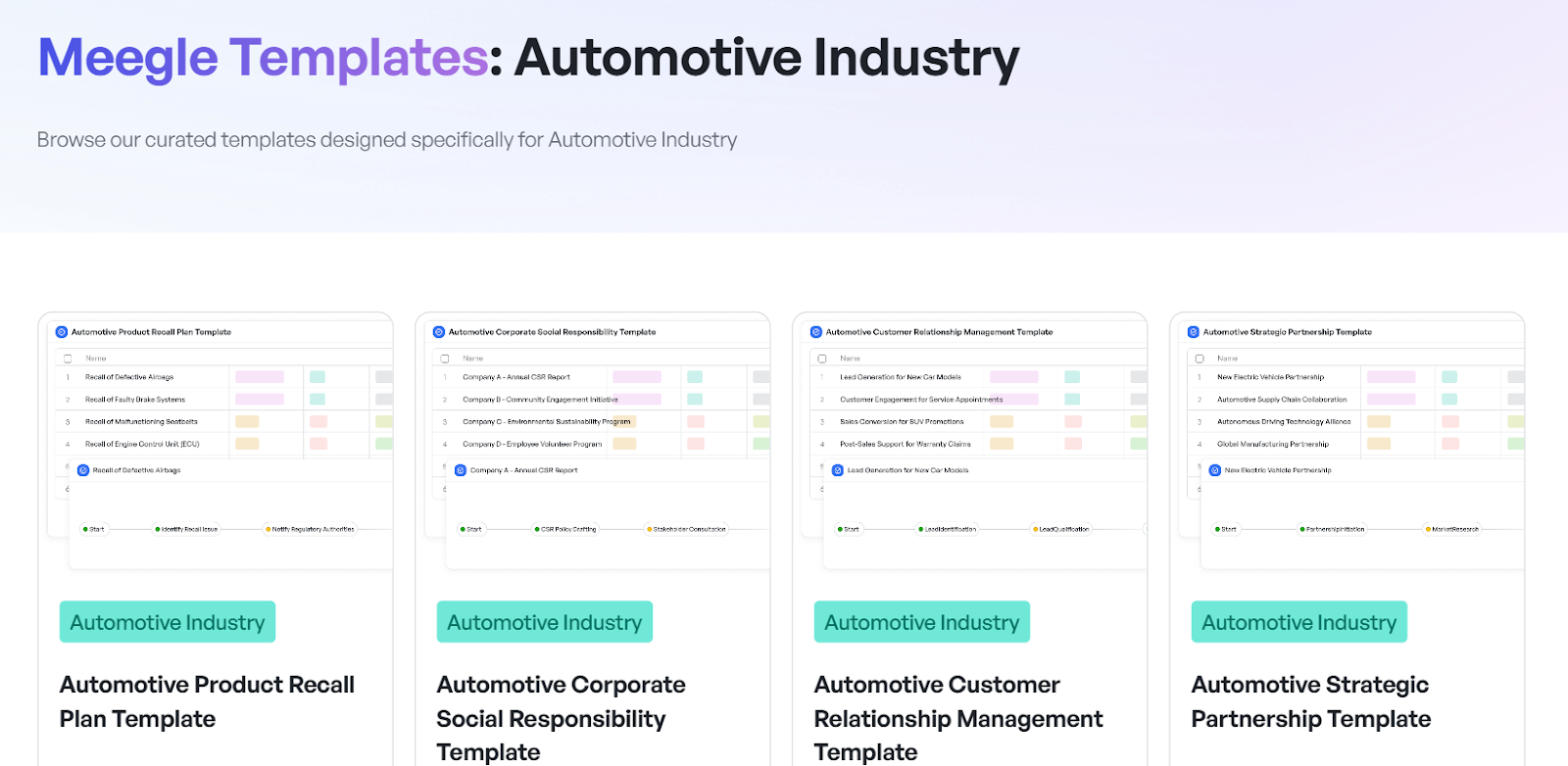

The right tools can help sustain lean by enabling teams to build repeatable, transparent processes using visual templates. From sprint retrospectives to cross-functional program tracking, you can scale what works and adjust what doesn’t.

Customizable pre-built templates

Customizable pre-built templatesBuild Clarity, Speed, and Alignment at Scale

Lean isn’t a checklist, it is a commitment to removing waste and building smarter systems. In the fast-moving world of automotive design and production, having a shared, visual workflow makes that commitment easier to uphold.

Bring lean to life with Meegle — model complex projects, stay effortlessly in control.

The world’s #1 visualized project management tool

Powered by the next gen visual workflow engineRead More

Check All BlogsStart creating impactful work today