How To Implement Lean In Construction: Boost Efficiency and Cut Waste with Visual Workflows

The construction industry faces a unique set of challenges—from tight project timelines and complex coordination among multiple teams to strict budgets and compliance demands. Managing these projects requires a high level of organization and real-time visibility into progress.

Lean principles offer a practical approach to reduce inefficiencies and improve collaboration in construction workflows, enabling teams to deliver projects on time and within budget.

This article explores how lean methods apply to construction, highlights common pain points, and shows how visual workflows help project managers and operations leaders maintain control and clarity throughout complex construction projects.

Understanding Lean Principles in Construction

Lean originated in manufacturing, but its core idea, “eliminating waste and improving flow,” translates well to construction. The main goal of lean in construction is to deliver maximum value to the client by optimizing processes and minimizing activities that don’t contribute to project outcomes.

Typical wastes in construction include delays, rework, excess inventory of materials, inefficient labor allocation, and poor communication within the team. Applying lean principles means focusing on:

- Reducing unnecessary steps or activities that don’t add value

- Improving communication and transparency to avoid mistakes and delays

- Optimizing scheduling and resource use to reduce downtime

- Continuously improving processes based on real-time feedback

The nature of construction projects—often large-scale, with many subcontractors and suppliers—makes it critical to have clear workflows and shared understanding among all stakeholders.

Common Challenges Lean Addresses in Construction

Construction projects often struggle with:

- Schedule delays: Changes, miscommunications, or unforeseen issues cause cascading schedule impacts

- Material waste: Overstocking or poor handling of materials leads to cost overruns

- Poor collaboration: Fragmented communication between architects, contractors, suppliers, and owners causes inefficiencies

- Limited visibility: Project managers and teams lack a unified view of task status and resource allocation

- Rework: Errors or unclear instructions require expensive fixes and slow progress

Lean approaches help address these challenges by focusing on workflow clarity, early detection of bottlenecks, and transparent communication.

Visual Workflows: A Practical Tool for Lean in Construction Management

Visual workflows offer a powerful way to implement lean principles in the construction industry. By mapping out each phase of a project—from initial design and procurement to on-site construction and final handover—teams can create a shared understanding of every task, timeline, and responsibility. This clarity helps reduce waste, improve coordination, and prevent missteps before they happen.

Rather than relying on fragmented systems or siloed communication, visual workflows bring everything together in one clear view.

Teams can break down complex processes into manageable tasks, define dependencies, and track progress in real time. This supports lean goals like continuous improvement, efficient resource use, and enhanced project transparency.

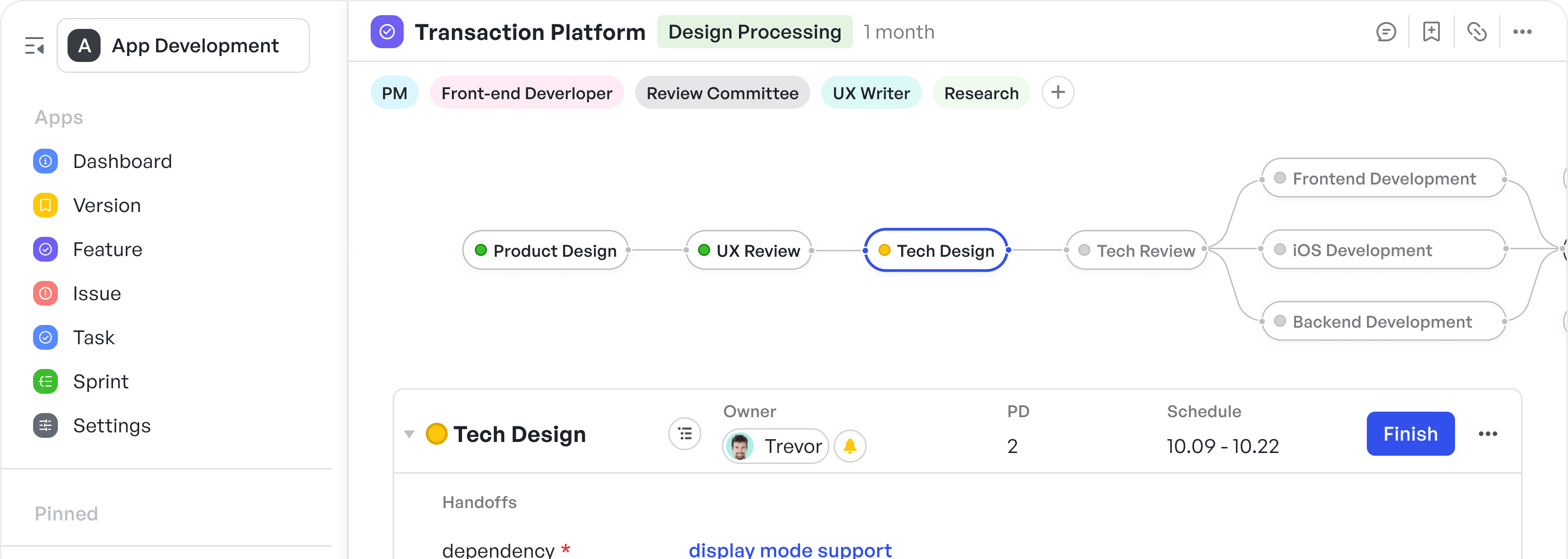

Construction workflow nodes in Meegle

Construction workflow nodes in MeegleKey Benefits of Visual Workflows for Lean in Construction Teams

- End-to-End Project Visibility: Starting from planning to completion, teams can see the entire value stream in one place, ensuring everyone understands the broader context and their role within it.

- Streamlined Communication & Collaborative Planning: Real-time updates and shared access reduce information silos and help teams coordinate across departments more effectively.

- Workflow Efficiency & Task Clarity: Complex construction processes are broken into actionable, clearly assigned steps, minimizing confusion and duplication of effort.

- Optimized Resource Utilization: Visual timelines and dependencies allow for better planning of labor, equipment, and materials, reducing idle time and avoiding overuse.

- Faster Identification of Bottlenecks: Teams can spot potential delays or blockers early, enabling faster adjustments and keeping projects on schedule.

- Improved Accountability & Lean Execution: When tasks are visually assigned with deadlines and dependencies, teams stay more aligned with lean values such as eliminating non-value-added work and focusing on flow.

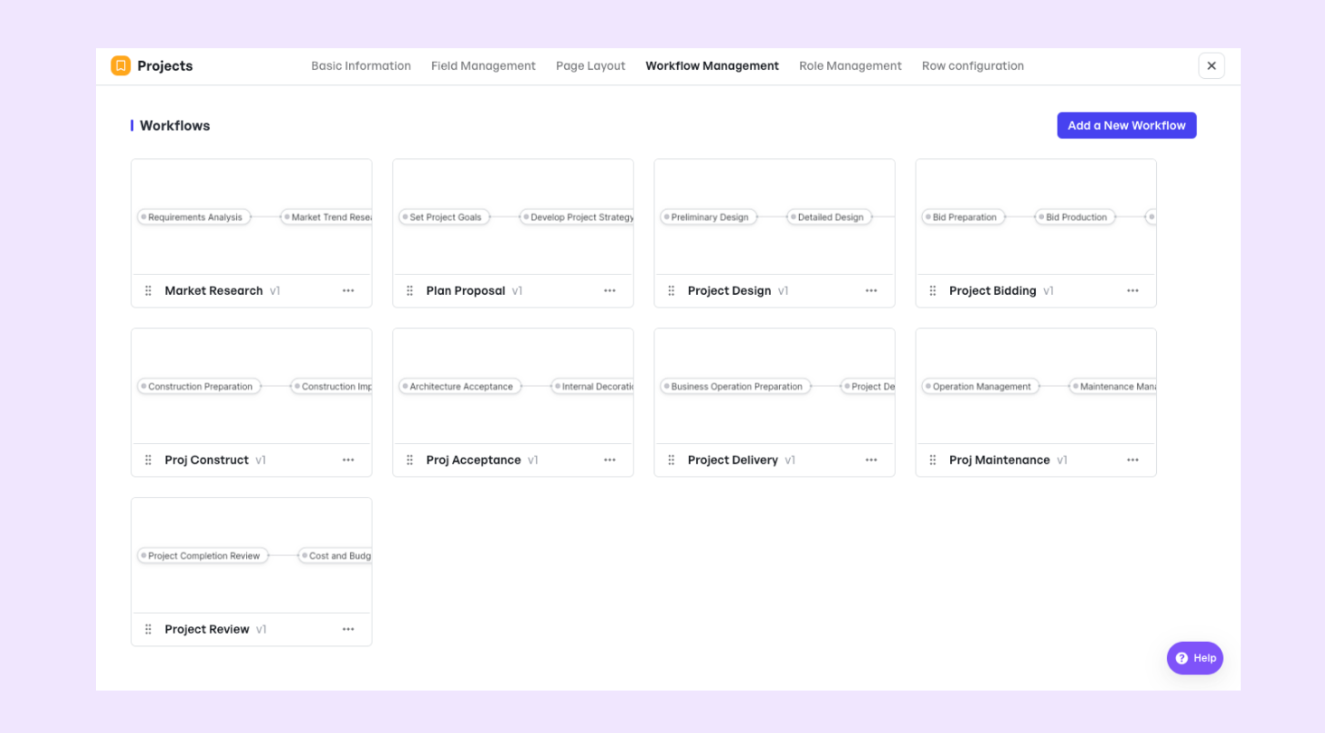

Overview board of the significant elements of a construction project

Overview board of the significant elements of a construction projectSupporting Lean in Construction Management with Flexible and Usable Tools

Construction workflows often involve complex processes and many moving parts, making flexible tools essential. An effective tool balances usability and complexity, adapting to different project sizes and team needs.

For operations directors, project managers, and executives, such tools provide:

- Ease of Use: Intuitive interfaces that don’t require extensive training but can handle complex construction projects efficiently

- Collaboration Across Teams: Seamlessly connects on-site crews, subcontractors, and office-based staff within a unified platform

- Customization: Allows adaptation of templates to specific construction phases such as design review, procurement, or quality inspections

- Tracking & Reporting: Offers clear indicators to monitor task progress, approvals, and delays

- Integration Capabilities: Easily integrates with other software commonly used in construction, ensuring smooth data exchange

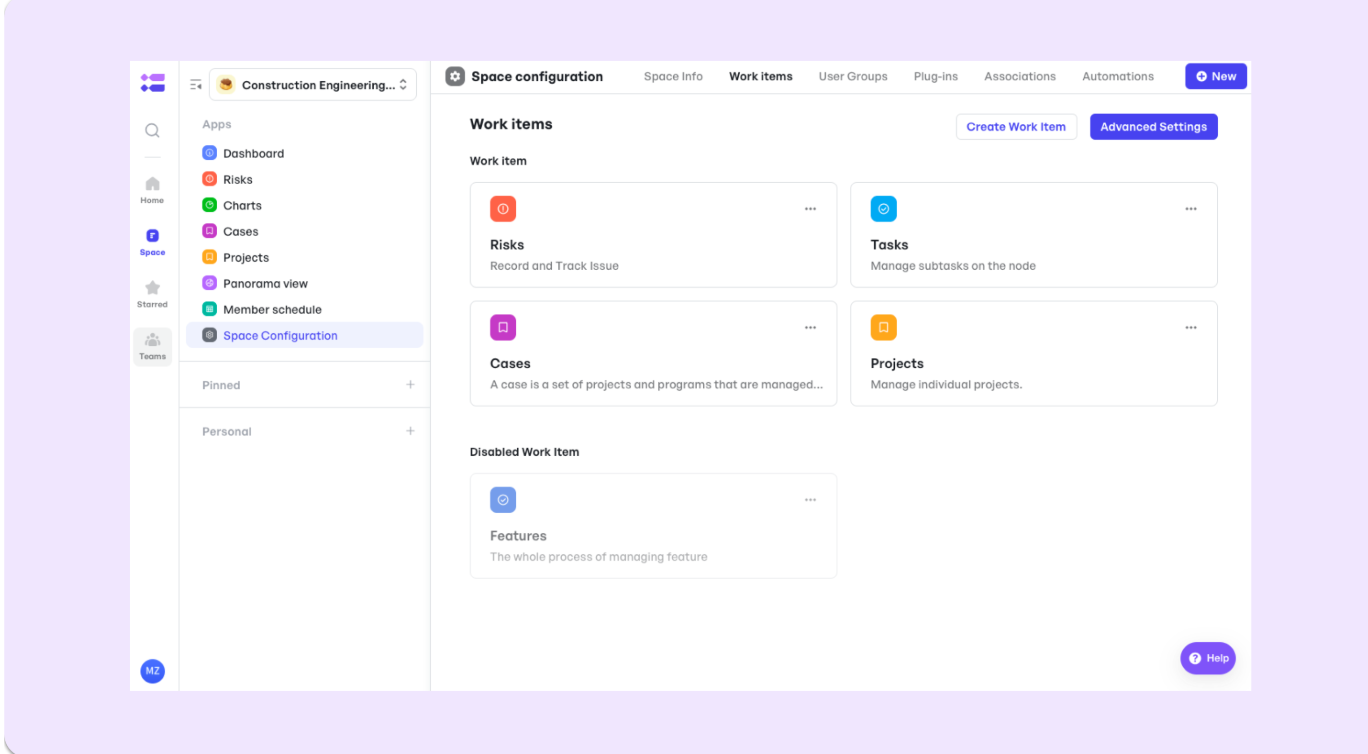

All your tools, tasks, and teamwork are streamlined in one visual workspace.

All your tools, tasks, and teamwork are streamlined in one visual workspace.By treating business processes as valuable assets and enabling clear visibility and collaboration, these tools help construction firms improve control, reduce waste, and deliver projects more successfully.

Lean Templates You Can Use Today:

- Construction Project Management Template: Helps teams plan, track, and manage every phase of the project

- Construction Schedule Management Template: Keeps timelines on track with clear task dependencies, milestones, and deadline tracking.

- Site Safety Management Template: Ensures safety protocols are documented, assigned, and monitored effectively.

Browse all Construction Templates

Applying Lean with Visual Workflows: Practical Steps

To implement lean principles using visual workflows in construction:

- Map Your Current Processes: Document key workflows such as design approval, material ordering, inspection, and handover.

- Identify Waste Points: Use workflow visualization to spot delays, duplicated efforts, and unnecessary steps.

- Create Visual Workflow Templates: Build workflow templates in Meegle reflecting streamlined, optimized processes.

- Train Teams: Encourage team members to update and use the visual workflows consistently to track tasks and progress.

- Monitor and Improve: Regularly review workflows, gather feedback, and adjust processes to improve efficiency.

By making workflows visible and collaborative, teams spend less time chasing information and more time delivering results.

You might be interested in: 👉Best PM software for construction

The Impact of Lean in Construction on Business Outcomes

Adopting lean methods through visual workflows leads to measurable improvements, such as:

- Reduced Project Delays: Clear task dependencies and real-time updates prevent bottlenecks.

- Lower Material Waste: Better procurement scheduling reduces excess inventory and spoilage.

- Improved Team Collaboration: Transparent communication reduces errors and rework.

- Enhanced Client Satisfaction: Projects finish on time and within budget, boosting reputation.

- Operational Efficiency: Project managers spend less time on firefighting and more on strategic oversight.

These benefits contribute directly to a stronger bottom line and sustainable growth.

You might be interested in: 👉Construction project management template

Gain Control and Clarity in Your Construction Projects with Visual Workflows

Lean in construction depends on clarity and collaboration at every stage. Tools that provide a clear overview of the entire project, enable progress tracking, and support seamless communication help teams apply lean principles effectively without adding complexity.

For mid-market and enterprise construction companies, adopting such solutions means better control over complex projects, reduced waste, and improved operational efficiency—leading to stronger outcomes for clients and stakeholders.

Bring lean to construction with Meegle — manage projects better, faster, smarter.

The world’s #1 visualized project management tool

Powered by the next gen visual workflow engineRead More

Check All BlogsStart creating impactful work today