Lean in Manufacturing: Driving Efficiency and Quality in Modern Production

Manufacturing is the backbone of many industries, yet it’s often challenged by inefficiencies, waste, and rising costs. Lean manufacturing offers a proven approach to streamline operations, reduce waste, and enhance product quality. In this article, we explore the core principles of lean in manufacturing, its benefits, and practical ways to integrate lean thinking into your organization’s workflows.

To truly harness the power of lean manufacturing, it’s important to understand its core principles, common tools, and the practical benefits it delivers. Let’s explore each aspect in detail to see how lean can transform your production processes.

Understanding lean in Manufacturing

Lean manufacturing is a management philosophy originally developed by Toyota in the mid-20th century. It focuses on maximizing value for customers while minimizing waste in all forms. Waste, or muda in lean terminology, refers to anything that does not add value to the final product — such as excess inventory, unnecessary movement, or defects.

The lean approach centers on creating more value with fewer resources by:

- Streamlining processes

- Enhancing flow

- Empowering teams

- Continuously improving operations

Core Principles of lean in Manufacturing

Lean manufacturing is built on five fundamental principles, which guide organizations in transforming their production systems:

1. Specify Value

Value must be clearly defined from the customer’s perspective. What features or qualities are essential, and what processes add real value? This clarity helps prioritize activities that directly contribute to customer satisfaction.

2. Map the Value Stream

Mapping the entire production flow from raw materials to finished goods helps identify non-value-adding steps. By visualizing the value stream, companies can pinpoint bottlenecks and waste sources.

3. Create Flow

Smooth, uninterrupted flow ensures products move efficiently through the manufacturing process. Eliminating delays and downtime reduces cycle time and increases responsiveness.

4. Establish Pull

Instead of producing goods based on forecasts, lean encourages a pull system where production is driven by actual customer demand. This reduces inventory costs and the risk of overproduction.

5. Pursue Perfection

Lean is a continuous journey. Organizations commit to ongoing improvements through feedback, problem-solving, and employee engagement to get closer to perfection over time.

Common lean Tools and Techniques in Manufacturing

Lean manufacturing employs a variety of tools to implement its principles effectively:

- 5S (Sort, Set in order, Shine, Standardize, Sustain): Organizes the workplace for efficiency and safety.

- Kaizen: Continuous, incremental improvements led by frontline employees.

- Kanban: Visual signals to control inventory and workflow.

- Value Stream Mapping: A detailed visualization of production steps to find inefficiencies.

- Just-In-Time (JIT): Producing only what is needed, when it’s needed.

- Poka-Yoke: Error-proofing methods to prevent defects.

These tools work together to reduce waste, improve quality, and foster a culture of problem-solving.

Trust us—you’ll want to see this:👉Deep Dive on Kanban

Benefits of lean in Manufacturing

Organizations that adopt lean manufacturing often see multiple advantages, including:

- Reduced Costs: By eliminating wasteful steps and excess inventory, companies save on materials, labor, and storage.

- Improved Quality: Lean’s focus on error-proofing and continuous improvement leads to fewer defects and higher customer satisfaction.

- Faster Time-to-Market: Streamlined workflows accelerate production cycles and responsiveness to market changes.

- Employee Engagement: Empowering teams to identify and solve problems boosts morale and ownership.

- Flexibility: Lean systems can adapt more quickly to changes in demand or product design.

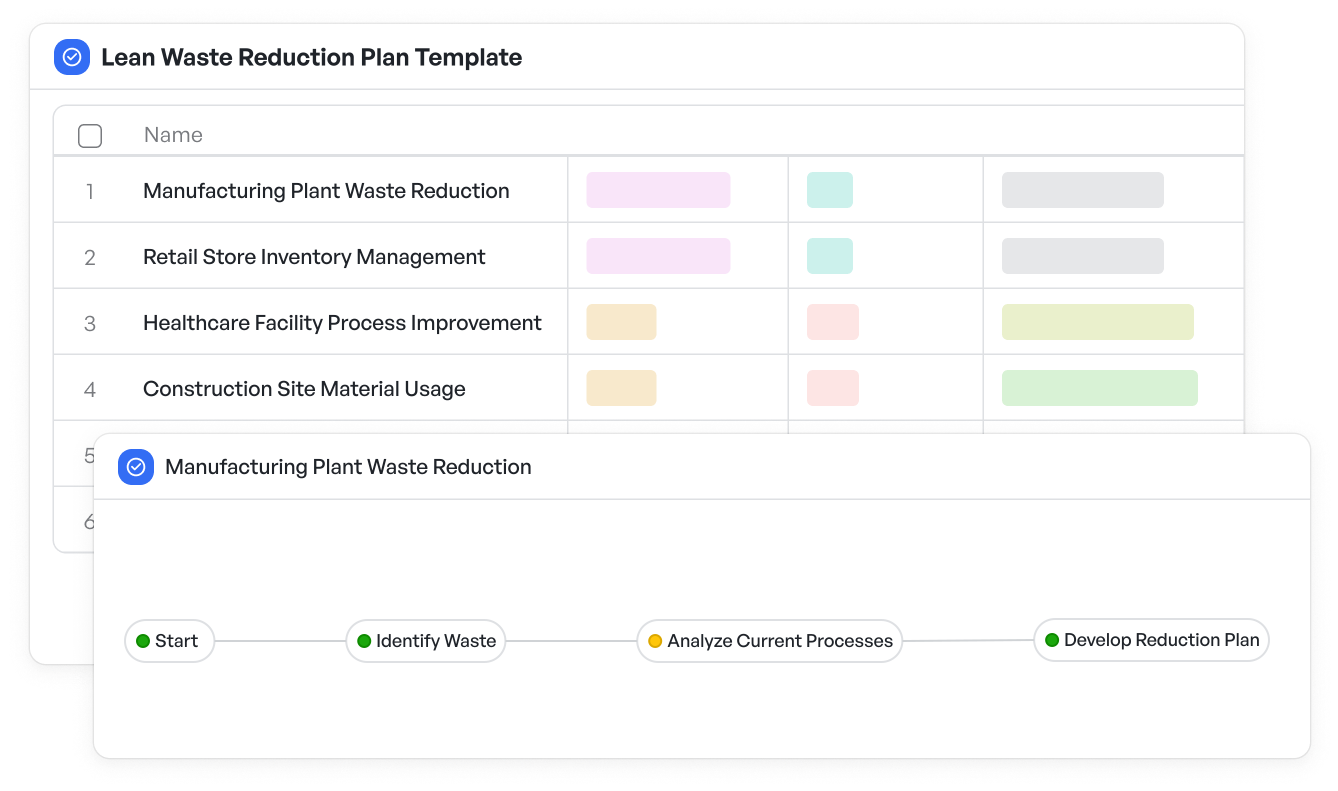

Implementing lean with Data-Driven Collaboration

Successful lean transformation requires alignment across teams and visibility into workflows and performance. Software tools play a key role in organizing lean initiatives and sustaining improvements.

Here’s where Meegle’s templates can support your lean manufacturing efforts:

- Value Stream Mapping Template: Easily document and analyze your production flow to identify waste and improvement areas.

- Kaizen Event Planner: Structure your continuous improvement initiatives with clear goals, action plans, and feedback tracking.

- 5S Audit Checklist: Standardize workplace organization and regularly evaluate compliance and progress.

- Problem-Solving Log: Capture issues and root causes systematically to enable focused resolutions.

By leveraging such templates, your teams can maintain clarity, measure progress, and accelerate lean adoption across departments.

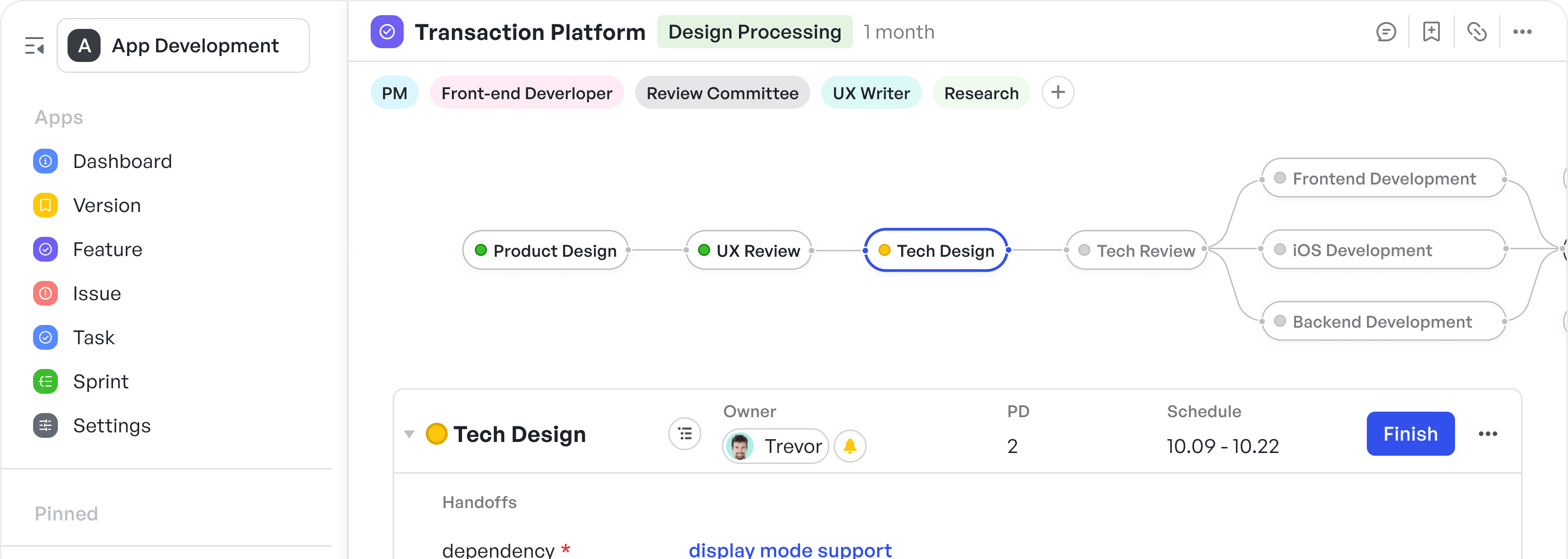

Lean Manufacturing project plan template from Meegle

Lean Manufacturing project plan template from MeegleTo get the full strategy breakdown check out, lean Manufacturing project plan template

Challenges in lean Manufacturing and How to Overcome Them

While lean manufacturing offers many benefits, organizations often face hurdles such as:

- Cultural Resistance: Lean requires a mindset shift toward continuous improvement and employee empowerment, which can meet resistance.

- Sustaining Momentum: Without proper tracking and accountability, lean initiatives risk losing steam over time.

- Integration with Legacy Systems: Older equipment or processes may be hard to adapt to lean workflows.

Addressing these challenges involves strong leadership support, clear communication, ongoing training, and robust tools that facilitate transparency and collaboration.

Embracing lean in Manufacturing for Peak Efficiency

Adopting lean manufacturing principles transforms production from a cost center to a competitive advantage. It builds a foundation for sustainable efficiency, quality, and agility—qualities that are essential in today’s fast-changing markets.

By combining lean philosophy with structured, data-driven workflows, your organization can unlock new levels of performance. Meegle’s templates provide practical frameworks to implement, track, and improve lean processes systematically.

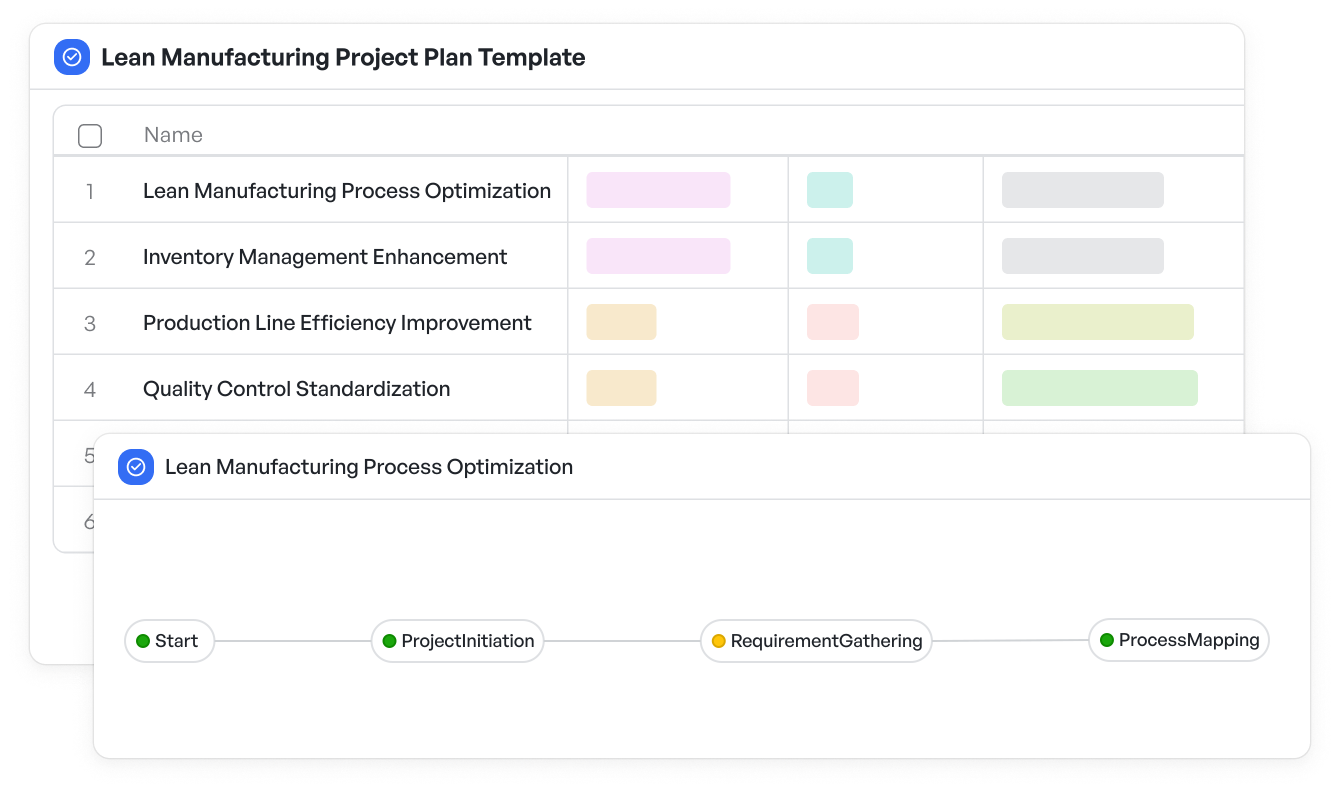

Automotive Lean Manufacturing Template from Meegle

Automotive Lean Manufacturing Template from MeegleFound something cool for you: Automotive Lean Manufacturing Template

Unlock Continuous Improvement and Operational Excellence

Implementing lean manufacturing is a strategic investment in your organization’s future. By focusing on value, reducing waste, and empowering teams, you create a culture of continuous improvement that leads to better quality, faster delivery, and cost savings. Using Meegle’s templates can simplify your lean initiatives, helping you track progress and sustain momentum.

Start your journey towards operational excellence today.

Meegle's waste reduction template

Meegle's waste reduction templateThis one’s worth a look: waste reduction template

Ready to simplify your lean manufacturing journey?

Elevate your lean strategy with Meegle — streamline workflows and accelerate performance, starting now.

The world’s #1 visualized project management tool

Powered by the next gen visual workflow engineRead More

Check All BlogsStart creating impactful work today